Soundproofing of Machines, Equipment, Gensets and Chillers

Industrial machinery, generators, chillers, and compressors are integral to many operations, but they often come with a significant downside: noise. High noise levels from machinery can disrupt operations, affect worker safety, and create tension with neighbouring businesses or residential areas. Furthermore, excessive noise contributes to harmful working conditions, leading to increased use of personal protective equipment (PPE) and a higher number of worker sick days.

Challenges of Machinery Noise

The noise emitted by machines and equipment can exceed permitted levels, particularly when multiple units operate simultaneously. This not only impacts workers’ concentration but can also lead to penalties for exceeding environmental noise regulations. Noise from industrial equipment may also negatively impact productivity, worker health, and the overall environment in which the machines are located.

Tailored Soundproofing Solutions for Equipment

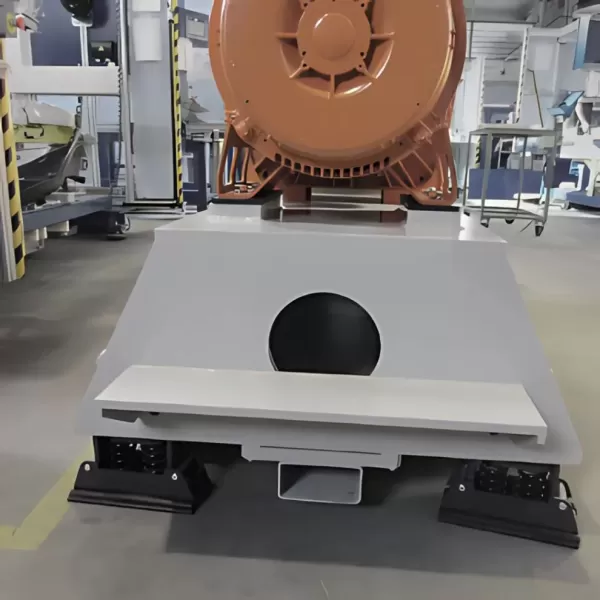

DECIBEL offers a range of soundproofing solutions for machines, gensets, chillers, compressors, and transformers to minimise noise pollution. These solutions can be passive or a combination of passive and active systems, depending on the specific requirements of the equipment and its environment.

Passive Systems: Our passive soundproofing systems include soundproof enclosures and Acoustic covers that are designed to be fitted around machinery components, making them quieter by default. These are widely applicable across various industries, including manufacturing, domestic, and transport equipment.

Active Systems: These advanced systems combine passive insulation with active noise cancellation techniques, using transducers and speakers to counteract airborne noise and vibrations. Active systems are particularly effective for air-transport ducts, heating, ventilation, and cooling systems, and are also applicable in the automotive and aviation industries.

Benefits of Industrial Soundproofing

Investing in industrial soundproofing offers numerous benefits. Not only does it help reduce the need for PPE, but it also improves working conditions by lowering stress levels, reducing sick leave, and enhancing overall worker productivity. Additionally, quieter equipment ensures smoother relations with neighbouring businesses and residents and helps businesses avoid legal complications related to noise pollution.

Specialised Soundproofing for Vehicles and Transport Systems

DECIBEL has extensive experience in providing soundproofing solutions for specialised vehicles, including cars, buses, trucks, rail, marine, and aircraft. Our lightweight yet highly effective systems are designed to comply with stringent industry standards while minimising the added weight to vehicles. Whether for increasing passenger comfort or meeting specific vehicle noise regulations, our industrial soundproofing solutions for transport systems are both efficient and compliant with relevant safety and combustibility standards.

Proven Expertise Across the Globe

With projects completed in more than 30 countries, DECIBEL has successfully provided soundproofing solutions for a wide range of machinery and equipment across diverse industries. Our work spans soundproofing gen-sets, chillers, compressors, and specialised industrial machines in factories, commercial buildings, and transport systems. DECIBEL’s tailored solutions have helped companies around the world reduce noise levels, ensure regulatory compliance, and improve working conditions. From local projects to large-scale international operations, we have earned a reputation for delivering effective, innovative noise control systems across all sectors.

Get Your Customised Soundproofing Solution Today

If you are seeking effective soundproofing for machinery, equipment, gensets, or chillers, DECIBEL can provide bespoke solutions tailored to your needs. Contact us at office@decibelinternational.com to learn more about how our soundproofing expertise can help reduce noise pollution in your industrial environment.

Related Product Groups

Soundproof Cabins, Enclosures & Noise Barriers

Custom made enclosures and barriers for production lines, machines, presses and more.

Acoustic Louvres & Silencers

Reduce loud noise and sustain airflow of engines, turbines, aggregates and cooling installations.

Anti-Vibration Mounts, Pads & Hangers

Anti-vibration materials for compressors, refrigerators, pumps, fitness equipment and others.

Sound Level Meters

Mid and high-class sound level meters for personal and professional use.