- Home

- »

- Projects

- »

- Machinery & Industrial Buildings

- »

- Soundproofing enclosure of punch press for Miba, Slovakia

Soundproofing enclosure of punch press for Miba, Slovakia

Project Overview

Miba Steeltec, a Slovak manufacturer of electrical industry parts and cables, faced a pressing issue at their factory—a 35-ton punch press generating over 105 dB/A on impact, far exceeding the safe workplace noise level of 85 dB/A. The constant exposure to this high noise level not only impacted employee concentration but also increased the risk of defects in production and posed serious health risks to workers. Miba management sought DECIBEL’s expertise to create a solution that would significantly reduce noise levels and improve working conditions.

Challenge

The challenge was to reduce the noise level around the press from a daily exposure of 89-90 dB/A to well below 80 dB/A, in line with workplace safety norms. The noise from the punch press had a direct negative effect on both workers’ health and overall productivity, and required a solution that maintained easy access to the machinery for regular maintenance.

Scope of Work

- Measure the noise levels around the 35-ton press

- Design a soundproofing enclosure that would reduce the noise to below 80 dB/A

- Ensure that the press remains accessible for servicing

- Install the enclosure under extreme factory conditions

Solution

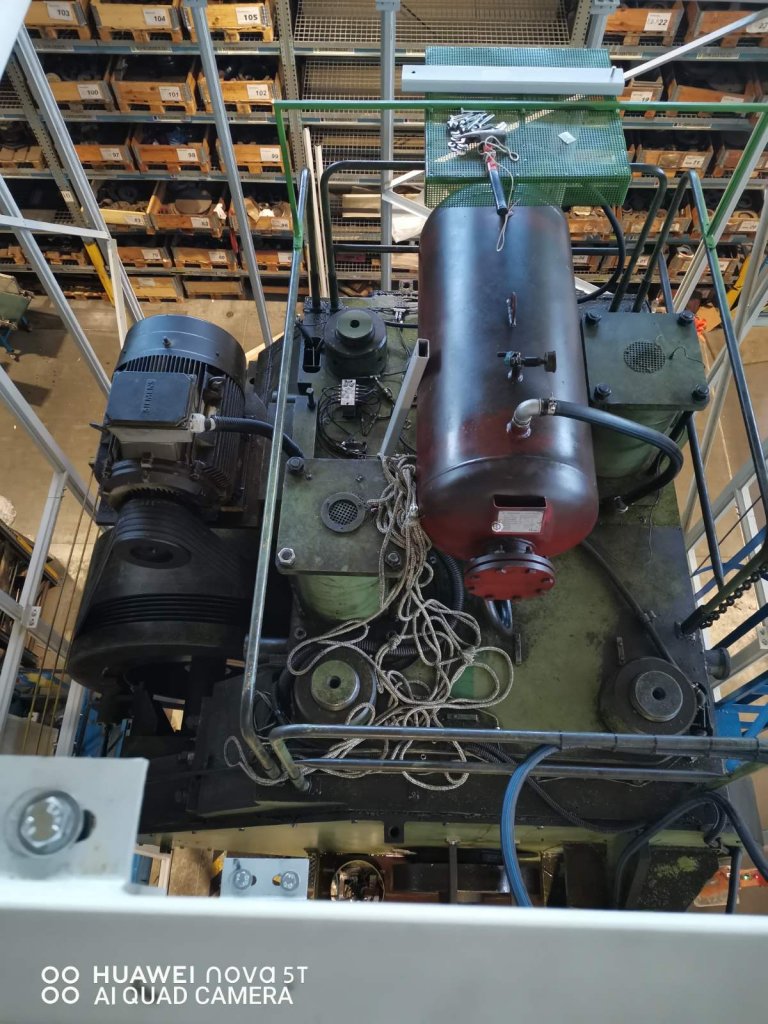

DECIBEL’s engineering team designed a custom soundproof enclosure using PZP panels and a standalone frame for Miba’s punch press. The solution was designed with removable walls and a specific bolt-nut fastening system using 3D elements, ensuring the press remained fully accessible for maintenance. Standing at 8.5 meters tall, this was the largest soundproof cabin DECIBEL had ever built, and the design was tailored to withstand the high impact noise generated by the press.

The installation posed additional challenges due to the factory’s extreme working conditions, with temperatures reaching 50 degrees Celsius. The team employed alpine methods to secure the installation team during the 8-day process. Despite these challenges, DECIBEL successfully installed the enclosure, significantly reducing the noise levels.

Results

Post-installation noise measurements confirmed that the sound level around the punch press was reduced to below 80 dB/A, achieving the desired goal. The positive impact was immediately felt by workers, who reported improved concentration and comfort levels. The plant management also observed a marked decrease in production defects. These results were so successful that Miba Steeltec invited DECIBEL to address another noise issue in a neighboring production area.

Importance of Soundproofing in Manufacturing Plants

In manufacturing environments, excessive noise can lead to decreased productivity, higher error rates, and increased health risks for workers. EU workplace safety regulations, including the EU Noise at Work Directive (2003/10/EC), mandate noise control measures to protect employees from long-term hearing damage. Effective soundproofing solutions like DECIBEL’s custom enclosures not only comply with legal requirements but also create healthier, more productive working environments, helping companies like Miba maintain high operational standards.