How to Soundproof a Ceiling- The Easiest and Most Effective Method for Ceiling Soundproofing

If ceiling noise keeps affecting your sleep, causes you stress and ruins your day-to-day focus you came to the right place. Soundproofing your ceiling is the solution. Public health evidence links environmental noise to sleep disturbance and cardiovascular risk, so bringing footfall and voices from above under control is a quality-of-life issue with measurable health impact.

Your peace of mind can be easily achieved, and we have all the effective solutions, like our C-MUTE SYSTEM™ 23 or C-BLOCK SYSTEM, that will fit just right.

In this guide, we’ll explain how ceiling soundproofing works, the key challenges you should know before starting, and the most effective solutions. You’ll learn how to choose the right approach for your project, whether it’s a new build, renovation, or retrofit.

Building Regulations for Soundproofing a Ceiling

First things first, there are regulatory expectations to consider. In the United States, many states and local jurisdictions adopt model codes such as the International Building Code (IBC), which sets baseline acoustic performance requirements for floor-ceiling assemblies in multi-unit residential construction. The IBC often references minimum STC (Sound Transmission Class) and IIC (Impact Insulation Class) ratings for assemblies separating dwellings. Contractors often use these as benchmarks even when testing is not mandated.

In new multi-family buildings or major renovations, some jurisdictions require field sound testing before issuing a certificate of occupancy, although many do not strictly enforce this requirement everywhere. Common practice still follows best-practice design: build a decoupled ceiling, increase mass, infill the cavity, and seal all edges and penetrations. Designing as if measurements will be required helps you hit or exceed expected ratings and avoid surprises during inspections.

Treat code targets and local requirements as a baseline, not your ceiling’s dollar target. Going beyond the minimum gives you margin for real-world variation and ensures your ceiling performs well even if workmanship or flanking paths introduce some loss.

Why aim higher than the minimum?

Field results are not laboratory numbers. Real buildings incorporate workmanship tolerances, junction details, and service penetrations that create flanking paths, so on-site ratings often vary even when the drawings appear perfect. International field standards, for example, ISO 16283 for airborne and impact tests and ASTM E336 for airborne, document how measurements are taken in finished rooms and why variability and repeatability matter.

In plain terms, small detailing slips or different source positions can shift the final number by a few decibels. Designing with headroom makes that variation harmless rather than project-threatening.

Flanking is the usual spoiler. ISO 10848 provides the framework for assessing sound that bypasses the main build through junctions and side paths. If beams, joists, corridor voids or penetrations are not isolated and sealed, energy skirts around even a heavy lining. Targeting a performance margin gives you resilience against those real-world paths and reduces post-occupation complaints.

Key Questions to Answer Before Soundproofing a Ceiling

Before you choose materials or a build-up, get a clear picture of what you are fixing. A short survey saves cost and avoids the wrong solution.

What is the existing structure?

Is it timber joists with a plasterboard lining, or a concrete slab with a suspended ceiling? Timber joists usually mean cavities, junctions and fixings that can carry vibration. Concrete tends to be heavier and better for airborne noise, but still needs help for impact and at service penetrations.

What noise are you actually dealing with?

- Airborne noise is speech, TV or music bleeding through the floor-ceiling system.

- Impact noise includes footfall, chair scrapes, and dropped objects that excite the structure.

If footfall dominates, you will prioritise decoupling and compliant hangers under the ceiling, or treatments above if you control the floor. If voices dominate, add mass, seal leakage and infill cavities.

How loud is it, and when does it occur?

You do not need a lab meter to start. A simple log of times, sources and rooms affected helps target the fix. Low-frequency footfall is often the pain point in evenings and weekends.

What space and services run above the ceiling?

Measure headroom and map obstructions. Downlights, sprinklers, extract ducts, pipes and cable trays all punch holes in isolation and can create flanking paths. Plan for backer boxes over recessed lights, sealed collars for services, and continuous perimeter seals.

Where are the flanking paths?

Noise can bypass a treated ceiling at the wall junction, through bulkheads, through corridor ceilings, or via a partial ceiling grid. Look for cracks at perimeters, open voids over partitions, and shared service runs. A successful design closes these routes with continuous linings and sealed junctions, not only thicker boards.

Things to Consider When Soundproofing a Separating Ceiling

Noise from upstairs is often dominated by impact events. Footsteps, chair movement and dropped objects energise the floor, then vibration travels into the ceiling below. You still need to control airborne noise such as speech and TV, but a good ceiling strategy tackles both. Field standards reflect this split. Airborne sound between rooms is measured with procedures such as ISO 16283-1 or ASTM E336, while impact is measured with ISO 16283-2 or ASTM E1007, with results condensed to single-number ratings used for comparison in different countries.

What does that mean in practice?

- For airborne control, add mass, seal leakage paths and infill cavities so sound finds no easy route through the build-up.

- For impact control, introduce resilient decoupling under the ceiling or treat the floor above.

Flanking is the hidden weak link

Even a heavy lining can underperform if vibration bypasses it through side walls, joists, beams, corridor ceilings or bulkheads. International guidance on flanking transmission shows how energy can skirt around your upgraded ceiling unless junctions are isolated and sealed. Plan for ceiling soundproofing isolation at perimeters, break rigid connections where feasible, and close every penetration so the secondary ceiling is truly independent.

Typical flanking paths to check

- Rigid connections at ceiling-to-wall junctions or continuous timber bridging.

- Open or shared voids above partitions and service risers.

- Unsealed perimeters, electrical boxes, ducts and light cut-outs.

Best Soundproofing Solutions to Reduce Unwanted Noise from Upstairs Neighbours

Start where the problem starts. Footfall and chair scrape are structure-borne first, so build your ceiling as an independent shield, then load it for airborne control, then lock every gap.

Decouple the ceiling to kill impact paths

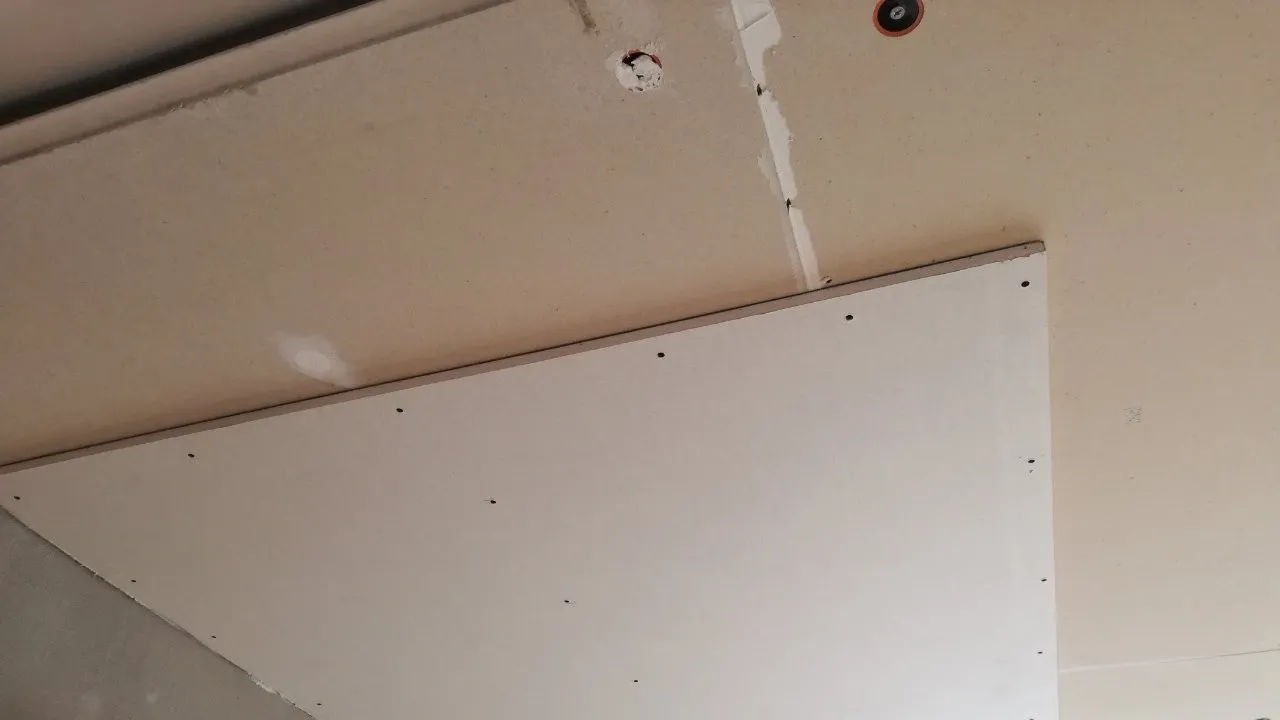

Install a secondary ceiling on point-connected isolators so vibration cannot pass straight through. DECIBEL’s C-MUTE SYSTEM™ panels use DClox™ fasteners that keep contact with the parent ceiling under 1%, which limits vibration transfer. The build is based on the proven mass-spring-mass principle and is validated through FEM simulation and independent EN ISO 10140 testing.

For an even stronger soundproofing option, C-BLOCK SYSTEM™ is DECIBEL’s most advanced ceiling sound insulation solution, engineered to deliver state-of-the-art noise reduction.

C-BLOCK SYSTEM™ is built on the principle of combining materials with different densities and elasticities, supported by vibro-insulating hangers and a strong frame. This multi-layered approach blocks and absorbs airborne noise while preventing vibrations from the parent ceiling from entering the panel.

Add mass and create a controlled cavity for airborne noise

Add dense layers and a consistent cavity infill. C-MUTE SYSTEM™ provides a slim, frameless panel that you can finish with plasterboard for extra mass while maintaining the decoupling. Mineral infill in the cavity helps tame resonances and improves wide-band airborne performance without stealing headroom.

Seal the perimeter and every penetration

A single gap can undo the lot. Use acoustic sealant around edges and at service cut-outs, and fit purpose-made backer boxes over downlights. DECIBEL accessories are tested as part of the system. DClant™ can add up to about 3 dB, DCvisco™ membrane a further 3 dB, and DCstrip™ isolation tape about 2 dB when detailed correctly.

Quick spec to copy

- Independent, point-connected secondary ceiling using C-MUTE SYSTEM™ panels on DClox™ isolators.

- Dense finishing layer, taped and sealed, with mineral infill in the void.

- Perimeter isolation and continuous acoustic sealing, with rated backer boxes for lights and sealed collars for services.

This three-step sequence is the sly way to silence upstairs. Break the vibration path, load the system for airborne control, then close every leak. It is thin and effective.

Upgrading Existing Ceilings: Retrofits and Plugging Leaks

When you are working to quieten noise from above without ripping out the structure, you need slim solutions that decouple the lining, add mass, and keep services practical. The goal is to lift airborne insulation and cut impact transmission.

Headroom-friendly retrofit methods that work

- Slim decoupled ceiling on resilient bars or clips. A shallow grid with resilient bars creates a flexible interface so the new lining is not rigidly tied to joists or the slab. Finish with two layers of dense board and a sealed perimeter to improve airborne performance while preserving headroom.

- Double board with mineral infill. Two staggered plasterboard layers on the resilient grid, plus mineral wool in the void, raise transmission loss across speech and TV frequencies. The bar system’s value is lost if it is short-circuited by hard fixings or over-tight perimeters, so follow spacing and edge-gap rules.

- Treat the floor above if you control it. A thin acoustic underlay beneath the floor finish reduces excitation of the structure, complementing the decoupled ceiling below.

- Service-friendly details. Plan downlights, access panels and ducts before you set your bar layout, then use acoustic backer boxes or rated hoods so every penetration remains sealed. This maintains the isolation that resilient systems provide.

The leaks that kill performance, and how to close them

Even a heavy, decoupled ceiling will underperform if sound skirts around it. Flanking transmission is noise that bypasses the main build-up via side walls, joists, shared voids or service routes, and it is a common reason field results lag behind laboratory data. ISO 10848 documents flanking measurement in the lab and field, and design guides repeatedly warn that workmanship and junction control decide real-world outcomes.

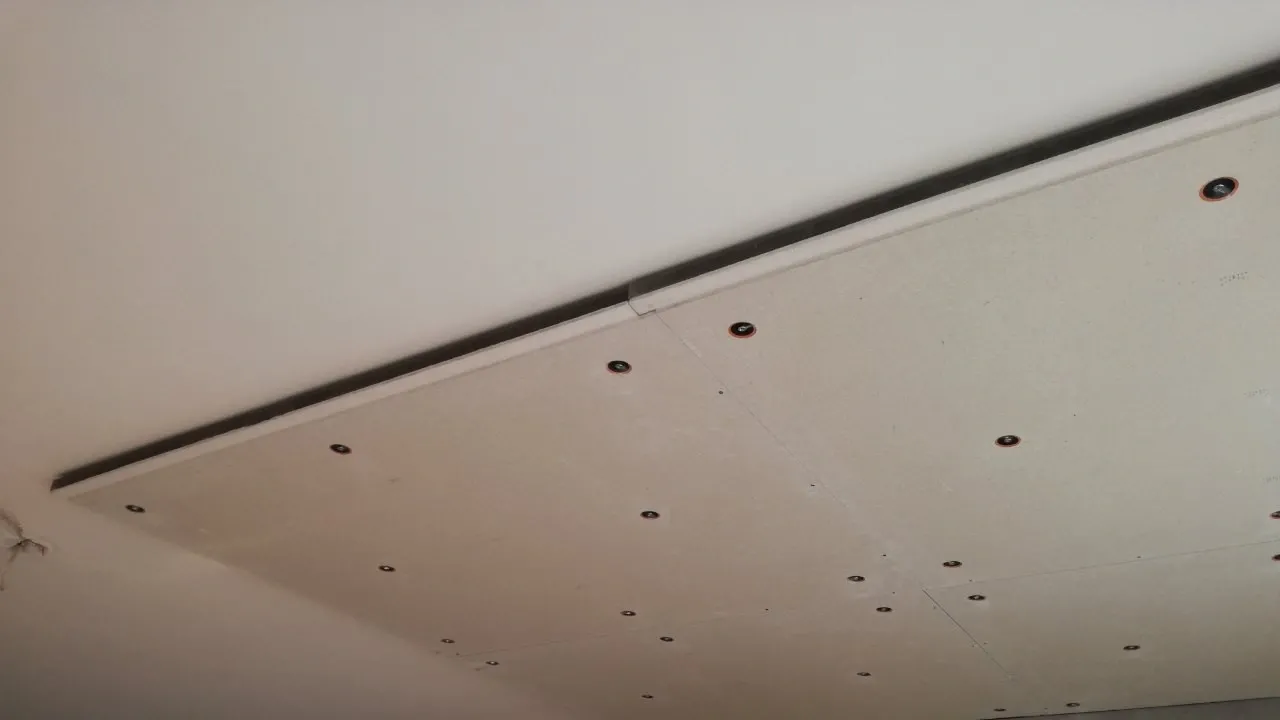

- Recessed downlights. Cut-outs act like open vents. Fit purpose-made acoustic backer boxes or hoods and seal to the lining. Avoid clusters of fittings. This preserves both isolation and fire strategy.

- Service penetrations. Ducts, pipes and cable trays transmit air and structure-borne energy. Use lined sleeves or collars, keep clear gaps around the lining, and seal with a suitable acoustic product at both faces.

- Poorly sealed perimeters. A continuous gap around the edge can undo the entire upgrade. Maintain a small controlled gap to avoid short-circuiting the bars, then seal it continuously with an acoustic sealant after boarding.

- Shared or open voids. Corridor ceiling voids, bulkheads and partial grids often connect rooms. Extend the isolated ceiling to real boundaries, or close voids with continuous, sealed linings to stop cross-talk.

- Ceiling tiles and lay-in grids. Perforated or unsealed tiles in corridors and plant areas are weak points. Where privacy or neighbour noise is a concern, replace with sealed, rated constructions or overlay with a decoupled lining that is continuous to the perimeter.

Bring these two strands together and you get a ceiling upgrade that is thin, practical and test-ready. Decouple first, add mass and infill, then hunt down every leakage route. Field measurement methods exist precisely to capture the effect of those details, so design for them from the start.

Playbooks by Ceiling Type

Successful ceiling upgrades follow the same core recipe. Add mass to block airborne sound. Decouple to break vibration paths. Dampen the lining so it does not ring. Infill cavities to control resonance. Seal all perimeters and penetrations.

Your Ceiling Type Matters

- Timber joists with plasterboard below: Create a shallow, independent lining on resilient bars or clips. Infill the void with mineral wool, then add two staggered layers of dense board and a continuous acoustic seal at the perimeter. Keep fixings clear of joists to protect the decoupling. If you control the floor above, a thin acoustic underlay further reduces excitation of the structure.

- Precast or cast-in-place concrete slab: Concrete already provides mass for airborne sound, so focus on vibration isolation. Hang an independent ceiling on resilient supports, add a double-board lining, and seal edges. Treat services carefully because penetrations in concrete can short-circuit the upgrade. Impact performance is usually the limiting factor, so verify with the tapping machine method.

- Steel–concrete composite or metal deck floors: Lightweight decks transmit impact readily. Use a decoupled ceiling below and, where possible, an acoustic underlay or floating treatment above. Control flanking at beams, deck edges and partition heads, since vibration can travel around the new lining unless junctions are isolated and sealed. ISO 10848 outlines how flanking at junctions can dominate if left unchecked.

- Suspended lay-in tile systems: Perforated or unsealed tiles are poor barriers. Where privacy and neighbour noise matter, overlay the grid with a continuous decoupled lining to the perimeter, or replace it with an isolated plasterboard ceiling. Use acoustic backer boxes over downlights and seal every service penetration before testing. Field methods capture these workmanship effects directly.

Tools You’ll Need to Soundproof a Ceiling

Getting a ceiling upgrade right starts with the right kit. Here is a concise, field-proven list and why each item matters.

- Acoustic hangers or resilient bars. Create a decoupled secondary ceiling so vibration does not pass straight through. Resilient bar systems are a recognised route to improve both airborne and impact performance when detailed and sealed correctly.

- High-mass boards. Two layers of dense board on the decoupled grid lift transmission loss across speech and TV bands. Field performance is verified with recognised airborne test methods.

- Mineral wool cavity infill. Controls void resonance and evens out mid-band performance. Typical specifications place mineral wool in the joist or hanger cavity above the new lining.

- Acoustic sealant and isolation tape. A continuous perimeter seal and sealed penetrations stop flanking air paths that can undo the build-up. Treat edges, back boxes, ducts and collars as critical junctions.

- Backer boxes or hoods for downlights. Recessed fittings are common leak points. Use purpose-made enclosures and keep cut-outs to a minimum to preserve isolation and fire strategy.

- Fixings rated for overhead work. Choose the correct anchors, screws and hangers for the substrate, and follow safe-handling and lifting guidance when boarding ceilings.

- Test kit if you are verifying results. Airborne insulation is measured on site using procedures such as ISO 16283-1 with a calibrated sound level meter and source. Impact transmission is checked with ISO 16283-2 using a standard tapping machine on the floor above. These methods give single-number ratings so you can compare before and after.

Pack this kit, plan your junctions, and you will have everything needed to build, seal and prove a genuinely quieter ceiling. If that feels too complicated, we can also lend a hand with design, consultation, installation and more!

Frequently Asked Questions

Is ceiling soundproofing expensive?

Costs vary with structure, headroom, and whether you need both airborne and impact control. Decoupled secondary ceilings with dense boards and sealed perimeters are mid-range, while adding resilient hangers and treating flanking paths raises cost but delivers more reliable field results that meet recognised test methods.

Is ceiling soundproofing effective?

Yes, when you combine the right methods. Field standards measure airborne insulation between rooms and impact insulation from footsteps above, so a design that adds mass, decouples, infills cavities and seals all junctions will show clear gains in those on-site ratings.

Can you soundproof a ceiling from noisy neighbours?

You can cut both voices and footfall significantly. Prioritise impact control with resilient hangers or a decoupled lining, then add mass and seal edges. Results are verified with recognised field tests for airborne and impact insulation.

What is the best way to soundproof a ceiling?

Follow a proven sequence: decouple the new ceiling from the structure, add two layers of high-mass board, infill the void with mineral wool, and seal every perimeter and penetration. This aligns with how field methods assess real-world performance rather than ideal lab samples.

What are the best materials for soundproofing a ceiling?

High-mass plasterboards, resilient bars or point isolators, mineral wool for cavity infill, acoustic sealant, and rated backer boxes for lights. Together, they improve airborne and impact ratings measured to ISO or ASTM field procedures.

Can you soundproof a ceiling without construction?

Lightweight add-ons can lower room echo, but will not stop neighbour noise because they do not add mass or decouple the structure. To change airborne or impact field ratings, you need a built-in lining that addresses structure-borne paths and leakage.

Can you soundproof a ceiling without damaging the walls?

Yes. A secondary ceiling can be hung from the slab or joists with perimeter isolation. The key is to maintain a continuous acoustic seal at the edges so sound does not bypass the upgrade via wall junctions.

Can you soundproof the ceiling without removing drywall?

Often yes. You can attach a decoupled grid or point isolators through the existing lining, then add dense boards, fill the void, and seal the perimeter. Plan service penetrations to avoid short-circuiting the decoupling.

Are there budget-friendly options for soundproofing a ceiling?

Entry steps include sealing perimeters with acoustic sealant and adding mineral wool where accessible. The best cost-to-benefit jump comes from a slim decoupled lining with double board, because it improves both airborne and impact performance in field tests.

How does the thickness of ceiling materials impact soundproofing?

More mass and a controlled cavity generally improve airborne insulation, while resilient separation improves impact performance. Field descriptors reflect these changes as higher airborne ratings and lower impact ratings.

Can soundproofing also improve insulation and energy efficiency?

Yes. Mineral wool used for acoustic cavities also provides thermal resistance, and sealing leakage paths reduces unwanted draughts, which is consistent with building guidance on sound and thermal performance.

Are there DIY methods for soundproofing ceilings that are effective?

Homeowners can seal edges, fit acoustic backer boxes to downlights, and add a simple resilient-bar and double-board lining if competent with overhead work and fixings. For tested outcomes and warranty, specialist installation is recommended.

Are there temporary solutions for soundproofing a ceiling, especially for renters?

Freestanding acoustic rafts and heavy curtains can reduce room echo and perceived loudness, but they do not change structural transmission. True neighbour-noise control requires decoupling, mass and sealing, which are fixed upgrades measured by field standards.

What are the potential health benefits associated with effective ceiling soundproofing?

Better sleep and lower stress are the main gains. Public health and research bodies link environmental noise to sleep disturbance and cardiovascular risk, so reducing intrusive noise at night is beneficial for well-being.

Ready to quieten the ceiling above for good? Tell us about your structure, headroom and noise type, and we will design a slim, testable specification that delivers real, measured results. Reach out to DECIBEL for a free consultation.