Innovations in Soundproofing Materials and Technologies

As costs of construction, materials and labour continue rising and space becomes ever tighter, decision-makers face the expectations of their valued customers. Regulations on environmental impact and sustainability are adding extra demands, while users demand high acoustic performance without every panel or wall eating into the already squeezed usable space. The old approach of piling on mass, thickness or expensive materials is becoming harder to justify.

This article will explore recent breakthroughs in soundproofing materials and technologies that deliver better sound control using thinner, lighter, or more sustainable solutions. You’ll learn about innovations that offer excellent noise reduction for less cost or smaller footprints and how to evaluate return on investment effectively so that your spend gives maximum benefit.

Market Trends & Demands Driving Innovation

Innovation in soundproofing materials and technologies is not happening in a vacuum. Increasing regulatory pressure, environmental expectations, and budget constraints are pushing decision-makers to demand solutions that do more with less.

Market Size & Growth Outlook

The global industrial noise control market is forecast to grow rapidly. According to Future Market Insights, the market is projected to reach USD 12.70 billion by 2035 from about USD 6.88 billion in 2025, with a compound annual growth rate (CAGR) of ~6.3%.

In Europe, the noise control systems market was valued at around USD 5.1 billion in 2022, which is roughly £3.8 billion at current exchange rates. It is expected to rise to about USD 8.3 billion by 2030, equivalent to approximately £6.1 billion, reflecting strong growth driven by stricter noise regulations.

Pressure Points Driving Innovation

Several pressures are pushing innovations in soundproofing:

- Space constraints in industrial or urban environments where bulky insulation or thick panels impractical.

- Regulatory requirements, especially in Europe, where worker safety laws, environmental noise directives, and public health norms force compliance and frequent audits.

- Environmental and sustainability concerns, meaning materials must have lower carbon footprints, be recyclable or made from bio-based waste products.

- Operational cost concerns, including installation, maintenance, and the cost of downtime, lighter, easier-to-install, durable materials can reduce total lifecycle cost.

Material Innovations: Breaking the Trade-off Between Thickness, Weight & Performance

Many traditional soundproofing materials depend on heavy, thick, or bulky constructs to block sound. Recent advances show that it is possible to maintain or improve sound insulation while reducing weight, thickness, or cost. The following are material innovations focused specifically on soundproofing (blocking sound from entering or escaping).

Nanofibre & Ultralight Layers

Recent research into nanofibre nonwoven fabrics (NF-NWFs) shows that adding nanofibre layers to lightweight base materials significantly increases transmission loss (TL) without adding much mass or thickness. A study of NF-NWFs made with microfibrillated cellulose found that by optimising porosity, bulk density and flow resistivity, one can achieve meaningful sound insulation gains.

This kind of ultralight layer is promising wherever constraints on wall depth or weight exist. These materials might supplement or overlay existing partitions to improve their soundproofing without replacing them.

Research details include:

- Studies show that flow resistivity, porosity and bulk density are the dominant factors in TF (transmission loss) for NF-NWFs.

- Experimental results: some NF-NWF samples showed measurable TL in standard laboratory setups, validating theoretical models like the Simplified Limp Frame Model (SLFM), meaning that the design can be optimised without guesswork.

These ultralight nanofibre materials are especially helpful for retrofits, tight spaces, or where reducing bulk is essential while still achieving soundproofing goals.

Wood Composites & Bio-Based Soundproof Panels

Bio-based panels using wood composites or natural fibres are not just for aesthetics or environmentally friendly marketing; recent studies demonstrate reasonable sound insulation (blocking) performance per unit thickness. While many earlier works focus on absorption (interior acoustics), newer research examines the sound reduction index/transmission loss of these composites.

Examples:

- An investigation of natural fibre reinforced composites (using hemp, wood fibre, etc.) showed that certain sandwich-panel designs can block airborne sound in mid to higher frequencies (in the third octave bands around 1-2 kHz). Experimental TL data suggest wood composite panels can perform similarly to heavier synthetic equivalents in those bands.

- Studies of glued laminated bamboo ("Glubam") and Spruce-Pine-Fir (SPF) panels show that glazing such bio-based panels with cavity or double layers can produce sound insulation useful for partitions or external wall facades. They do somewhat less well at low frequencies but perform respectably in mid-bands.

Advantages include lower embodied carbon, potentially lower cost in regions with abundant bio-resources, and lighter weight compared with traditional all-metal or thick concrete or masonry partitions.

After years of experimentation, research and testing, DECIBEL has developed and patented a fully biodegradable, innovative soundproofing material. It is produced from 100% environmentally friendly raw materials, which can enrich the soil if discarded.

The novel panel has excellent sound insulation and sound absorption, air and vapour permeability, anti-fungicide, hygroscopic and hardness. Its thermal insulation properties are comparable to those of styrofoam, its sound insulation properties are comparable to those of thick pre-wall cladding, its vapour permeability is like stone wool, and it has an easy installation.

The full release of the product to the open market is coming. While DECIBEL is building a new factory that would scale the production of the new material, we are already working on our first soundproofing project with it.

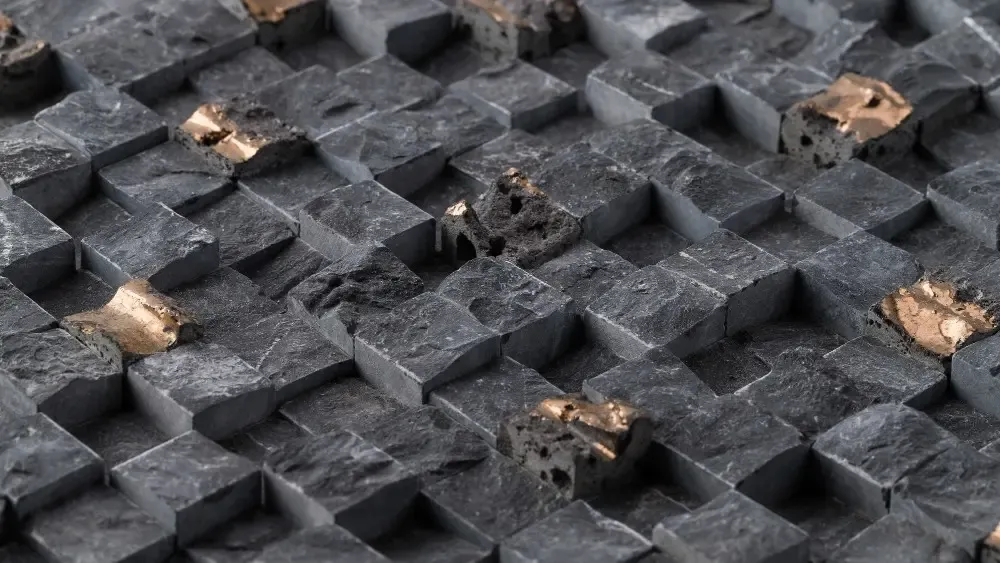

Metamaterials & Periodic Panels Optimised for Insulation

Metamaterials, engineered structures whose architecture (geometry) imparts acoustic properties, are emerging as a way to block sound efficiently with less material.

- A recent paper on bioinspired periodic panels showed that panels using thickness-varying profiles or locally resonant attachments can significantly suppress sound transmission (airborne noise) over certain frequency bands, especially in the low-to-mid range. These panels allow lighter panels or thinner partitions to achieve sound reduction close to what heavier solid panels achieve.

- These optimised periodic panels also show more consistent performance with respect to the incidence angle of sound waves, which helps in real-world settings where sound hits walls from many directions.

These designs tend to cost more in design or manufacturing, but in many cases pay back via savings in material, reduced structure thickness, and lower installation costs.

Limitations & Considerations

While the above materials show promise for soundproofing, several challenges remain:

- Low-frequency sound (below ~125-250 Hz) remains difficult to block without mass or depth; many materials do well at mid and high frequencies but require support (mass, cavity, acoustic seal) to push performance at bass-heavy noise sources.

- Manufacturing scale, consistency of material properties (density, porosity) can vary; thermal and moisture stability is sometimes weaker in bio-based or ultralight materials unless properly treated or sealed.

- For external walls, weather, fire rating, and building regulations around insulation, moisture, and durability often impose constraints that lightweight or novel materials must satisfy.

Technological Innovations & Methods That Improve ROI

Emerging technologies and smarter production or design methods amplify soundproofing performance or reduce total cost. These innovations often unlock levels of noise control that passive materials alone struggle to achieve, especially for low frequencies, or they reduce maintenance and installation expenses.

Active Noise Control (ANC) & Smart Panels

Active Noise Control uses sensors (microphones) and speakers or actuators to generate waveforms that cancel unwanted low-frequency noise. It works best for steady or predictable noise sources such as machinery hum, HVAC, or urban traffic, though complexity and cost are higher than with purely passive treatments.

- Controlling the vibration of the casing of a washing machine using active methods reduced low-frequency noise significantly during its spinning cycle. Both passive isolators and active vibration control were used to achieve noise reduction at the source.

- Another example is implementing ANC in panels placed near high noise sources (e.g. substations). These panels generate counteracting sound waves to reduce perceived noise in nearby residential areas. Results show a meaningful reduction of annoyance from external sound sources.

Trade-offs include higher energy use, greater system complexity, need for calibration and maintenance. Also, ANC works better at low frequencies; its effectiveness drops as noise becomes more varied, sudden or broadband.

Constrained Layer Damping & Mass-Spring-Mass Constructions

Constrained layer damping (CLD) and mass-spring-mass assemblies are among passive methods that have benefited from recent optimisation. These approaches help reduce vibration transmission and radiated noise, improving performance for moderate weight and cost.

- A recent study, published in Shock and Vibration 2017 of vibration-damping using constrained layer damping on machine tool headstocks, showed that adding a thin damping material significantly reduced resonant response amplitudes (particularly of the first few modes) while keeping added weight relatively small. Optimisation allowed the weight of damping material to be halved with less than 25 per cent loss of damping performance compared to heavier treatments.

- Another paper from Scientific Reports 2023 describes a thin viscoelastic layer sandwiched between rigid or stiff constraining layers; these composite structures dissipate vibrational energy efficiently, reducing radiated sound without needing thick panels.

These methods especially help where vibration is a key path for noise (e.g. metallic walls, machinery casing). For ROI, they perform well because they often require less material, can be retrofitted and tend to last longer without needing replacement.

Sustainable & Recycled Material Integration

Sustainability is increasingly a key factor in soundproofing materials. Decision-makers want products that not only block sound well but also have a lower environmental impact, use recycled or bio-based inputs and offer cost savings across their lifespan.

Several recent studies show that natural or recycled composites are now achieving decent sound insulation (sound transmission loss, STL) rather than just absorption inside rooms.

A few examples:

- A study of recycled HDPE (high-density polyethene) combined with waste jute fabric created composite sheets with sound insulation (average STL) around 49-50 dB in lab testing at certain frequencies (neat rHDPE vs rHDPE + jute composite) while maintaining sheet densities in the 970-1,000 kg/m³ range. This demonstrates a barrier to airborne sound nearly equivalent to heavier or more expensive synthetic panels.

- Research into organic waste materials and panels using pine cone and walnut shell combined with gypsum or plaster board achieved sound transmission loss over 30 dB at frequencies between 500-8,000 Hz. Some composite forms of those materials exceeded 60 dB in specific shapes (concave or egg-shaped surfaces) in tests. That shows natural materials can become viable soundproof barriers when formed into suitable composite or geometric assemblies.

- Mycelium-based insulation boards grown on wheat straw with fungal species such as Pleurotus ostreatus or Ganoderma lucidum have delivered STL values from 46.4 to 59.7 dB at 1,000 Hz, depending on incubation times and growth conditions. Although performance in lower frequencies may be less strong, for many industrial or residential soundproofing tasks (machinery noise, traffic), this is a useful level of sound blocking.

Computational Modelling, Optimised Design & “Right-Sizing”

Design tools and computational modelling are helping performance be achieved more efficiently. “Right-sizing” means getting just enough material, just enough damping or absorption, without over-engineering, which reduces cost, material waste and installation time.

- In recent research, inverse multi-objective optimisation was used to design microperforated panels (MPPs) targeting low-frequency noise, while minimising fabrication cost. The optimisation yielded designs that balanced performance, cost and thickness so that the resulting panels were effective yet not oversized.

- Another study on Locally Resonant Acoustic Metamaterials shows computational design processes (multiscale homogenisation, model order reduction, topology optimisation) can create lightweight insulation panels that block unwanted frequency bands without needing massive material layers.

Design optimisation brings ROI by reducing wasted material, lowering shipping/installation cost, improving fit where space is limited, and ensuring performance matches the actual noise profile rather than generalised “over-kill”.

Evaluating ROI: What Matters to Decision-Makers

For facility managers or executives, the question of cost vs performance is not just about how much the materials cost upfront. It’s also essential to weigh installation, durability, maintenance, impact on usable space, regulatory compliance and ongoing operating overhead. A solution that looks cheap initially but fails fast or imposes high upkeep will rarely deliver value.

Life Cycle Costs: Durability & Maintenance

Choosing soundproofing solutions based purely on how well they perform on day one can be misleading. Over years of use, materials degrade, environments change, and maintenance or replacement becomes a significant cost driver. A high initial cost may be justified if the product lasts significantly longer or retains performance well.

Durability depends heavily on environmental exposure. Moisture, extreme temperature variation, UV exposure, or repeated mechanical stress can degrade acoustic foams, fabrics or adhesives. In one experimental study, biomass geopolymer-based insulation materials were subjected to cycles of humidity and mechanical load; some samples lost absorption performance, especially at higher frequencies, after repeated exposure.

Regulatory & Sustainability Incentives

Regulations and sustainability standards are increasingly pushing organisations to adopt quieter, greener materials. These policies not only protect health and well-being but also create financial and reputational incentives for using soundproofing technologies that are efficient, durable, and environmentally responsible.

The European Union’s Environmental Noise Directive requires member states to assess environmental noise, publish noise maps every five years, and prepare noise management action plans. These plans encourage the use of quieter products and improved building design to reduce noise exposure.

Public interest in noise reduction has also led to calls for stronger environmental health measures. The EU’s Zero Pollution Action Plan aims to reduce by 30% the number of people exposed to harmful transport noise by 2030, which drives demand for materials and technologies that can help achieve these targets.

OSHA’s Occupational Noise Exposure standard mandates employers implement hearing conservation programmes when worker exposure reaches or exceeds 85 dB averaged over an 8-hour workday. These regulations, while not always specifying particular materials, create a framework in which high-performance soundproofing is rewarded because it helps organisations comply with legal limits and reduce liability.

Investing Smarter in Soundproofing Innovation

As materials evolve and production methods improve, soundproofing and acoustic treatment are no longer about just piling on mass or adding expensive bulk. The real breakthroughs come from innovations that offer thinner panels, sustainable cores or active control without sacrificing performance.

For facilities where space, cost and environmental impact matter, choosing materials and technologies that perform well per pound, per square metre or per millimetre of thickness delivers much better return on investment.

When you combine thoughtful material selection, optimised design and careful engineering with long-term durability and regulatory foresight, you ensure your acoustic solution delivers consistent results, lower maintenance, fewer disruptions, and better user satisfaction. Acoustic comfort becomes a strategic asset, not an afterthought.

If you are ready to complete your facility or studio upgrade with solutions that are both high-performance and cost-efficient, DECIBEL offers bespoke acoustic assessments, detailed room modelling, and highly effective soundproofing systems. Reach out to us today!