- Home

- »

- Products

- »

- Noise control

- »

- Anti Vibration Mounts, Pads and Hangers

- »

- FM Pad - Anti-Vibration Mount for Wooden Floors

FM Pad - Anti-Vibration Mount for Wooden Floors

The FM Pad is an engineered anti-vibration element developed to reduce impact noise in wooden floor systems and lightweight partitions. Designed to minimise the transmission of footfall and structural vibration, it acts as a resilient connection point between wooden battens and the supporting floor structure. This separation eliminates acoustic bridges, significantly improving the sound insulation performance of floors and ceilings in residential and commercial buildings.

How It Works

FM Pad consists of metallic and elastic components connected to form a single resilient support. The elastic part is made from a specially formulated, non-ageing material that maintains elasticity and stability over time, ensuring consistent sound insulation performance. The metallic parts are treated with an anti-corrosion coating to provide long-lasting protection. When installed in series, the pads absorb and dampen vibrations caused by impact noise, preventing transmission through the structure below.

Key Benefits

- Effectively reduces impact and structure-borne noise in wooden floors

- Prevents the formation of rigid acoustic bridges

- Durable elastic material retains performance over time

- Anti-corrosion protection ensures long service life

- Easy to install with standard fasteners

- Improves both sound insulation and vibration isolation of floor systems

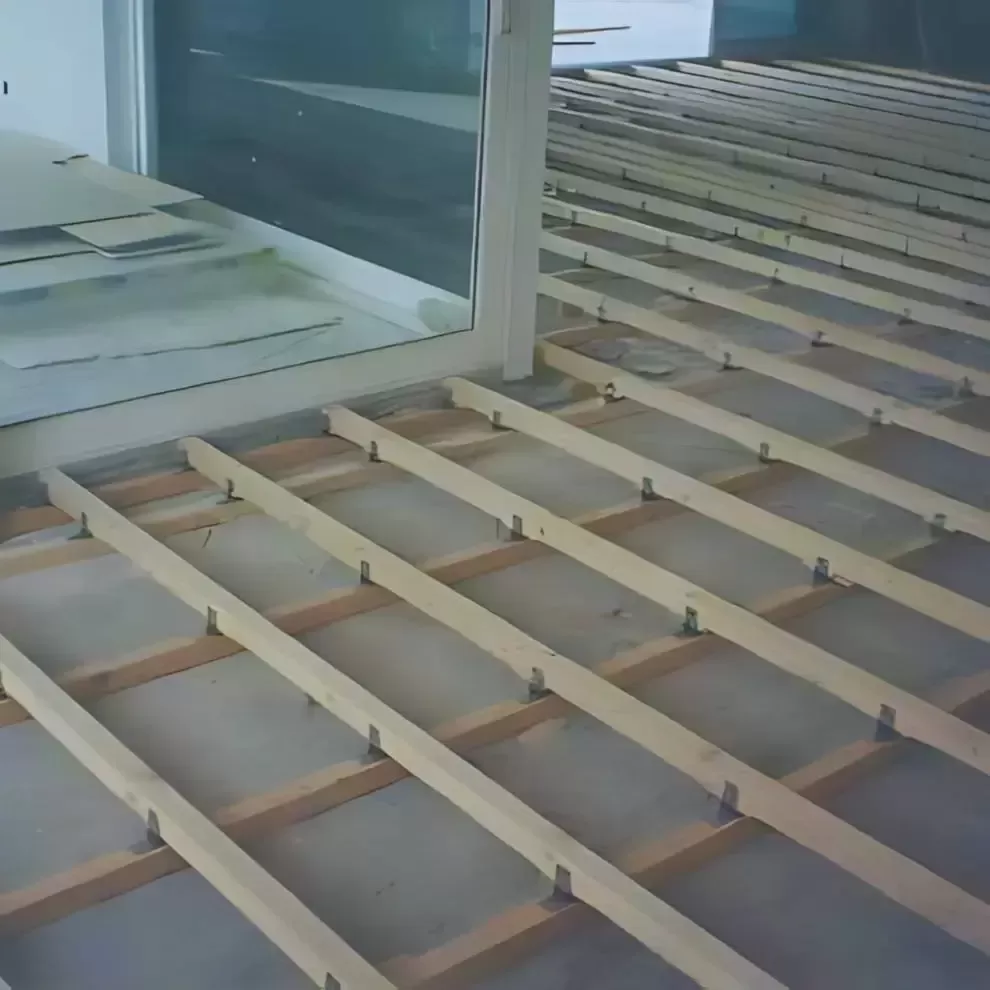

Installation Overview

FM Pads are arranged in parallel rows beneath the wooden battens, spaced approximately 400 mm apart when battens are positioned 330 mm apart. The lower strip of each pad is fixed to the floor or secondary wooden layer using stainless-steel nails or expansion bolts, while the primary wooden batten is secured to the upper strip with nails or screws. The spaces between battens must be filled with sound-absorbing material such as mineral wool. For optimal performance, the floor must be fully decoupled from walls using an elastic Vibro-band perimeter strip to prevent sound transmission through rigid contact points.

Key Specifications

- Composition: Metallic and elastic components with anti-corrosion coating

- Installation Spacing: 400 mm between pads (batten spacing 330 mm)

- Compatible Materials: Wooden battens and acoustic insulation layers

- Elastic Material: Non-ageing, high-resilience compound

- Mounting: Inox nails, screws, or expansion bolts

- Consumption Rate: 6–8 per m²

- Maximum Load: up to 8 kg per point

- Impact Sound Insulation Index (Lₙ,w): 53 dB

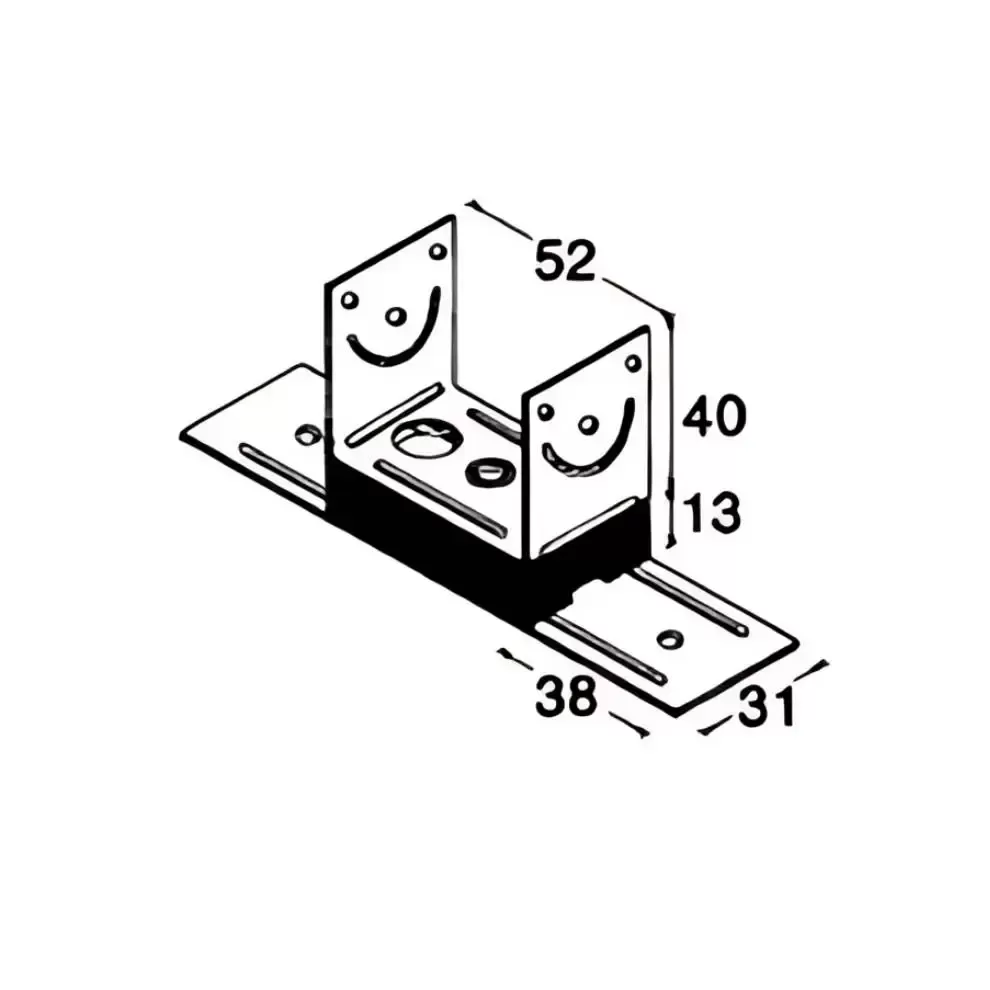

- Physical Dimensions: Height 53 mm | Width 52 mm | Depth 40 mm

Best Suited For

- Wooden floors in residential and office buildings

- Lightweight partition systems

- Renovation and retrofit projects requiring acoustic isolation

- Studios, auditoriums, and multipurpose halls

Precision Engineering for Quiet Floors

FM Pad delivers proven impact noise reduction and vibration isolation for wooden floor systems. Its combination of durable materials, mechanical reliability, and acoustic efficiency ensures long-term performance in demanding building environments.

Contact DECIBEL to integrate FM Pad into your next sound insulation design.

Technical data

| Dimensions: | |

|---|---|

| Consumption rate: | from 6 to 8 per m2 |

| Max. load: | up to 17 lbs per point |

| Impact sound insulation index: | LN, w = 53 dB |

Downloads

Technical data sheetRelated Projects

Floating Floor Soundproofing for Impact Noise Control