- Home

- »

- Products

- »

- Noise control

- »

- Soundproof Cabins, Enclosures and Noise Barriers

- »

- DBB™ – Soundproof and Acoustic Curtain

DBB™ – Soundproof and Acoustic Curtain

DBB™ is DECIBEL’s advanced soundproofing and acoustic curtain, combining high-performance noise reduction with flexibility and refined design. Developed for industrial, commercial, and residential applications, it offers a unique combination of soundproofing and sound absorption within a portable, modular structure.

The curtain effectively blocks airborne sound while reducing reverberation, making it suitable for use around machinery enclosures, studios, schools, and gyms. Its soft yet durable surface also improves safety in public spaces while maintaining a professional aesthetic.

How It Works

At the core of the DBB™ curtain lies high-density polyurethane (PU) foam integrated with a visco-elastic membrane, a configuration designed to block and dissipate sound energy simultaneously. The PU foam absorbs airborne and reflected noise, while the visco-elastic layer acts as a mass barrier, significantly reducing sound transmission.

The curtain is finished with a durable outer layer available in acoustic textile, vinyl, or glass cloth scrim, depending on the installation environment. This structure delivers reliable acoustic performance, achieving an Rw = 26 dB sound insulation index. DBB™ can be used as a permanent or mobile acoustic barrier, easily relocated as machinery, layouts, or worksite conditions change.

Key Benefits

- Combines soundproofing and sound absorption for dual acoustic performance.

- Lightweight yet effective, offering an Rw = 26 dB reduction in airborne noise.

- Constructed from PU foam with a visco-elastic membrane for enhanced insulation.

- Available with textile, vinyl, or glass cloth finishes for indoor or outdoor use.

- Flexible and modular, suitable for both fixed and movable applications.

- Optional magnets, eyelets, or Velcro allow easy attachment and repositioning.

- Provides additional thermal insulation and impact safety in public settings.

- Weather-resistant when specified with vinyl or glass cloth finish.

Installation Overview

DBB™ curtains can be installed using frames, suspended tracks, or fixed mounts, depending on the project’s acoustic and spatial requirements. The modular design enables individual panels to be joined or separated for tailored coverage.

Integrated accessories such as Velcro fasteners, eyelets, or magnetic seals make assembly quick and tool-free. The curtains can also be configured to include access openings or ventilation panels without reducing their acoustic performance.

Key Specifications

- Core composition: Polyurethane foam with visco-elastic membrane

- Outer finish options: Acoustic textile, waterproof vinyl, or glass cloth scrim

- Weight: 5.8 kg/m²

- Sound insulation index: Rw = 26 dB

- Thermal properties: Provides heat insulation

- Customisation: Optional integrated magnets, eyelets, or Velcro

- Installation: Suspended, framed, or fixed mount (removable and reusable)

- Maintenance: Easy to clean, reposition, or replace

Best Suited For

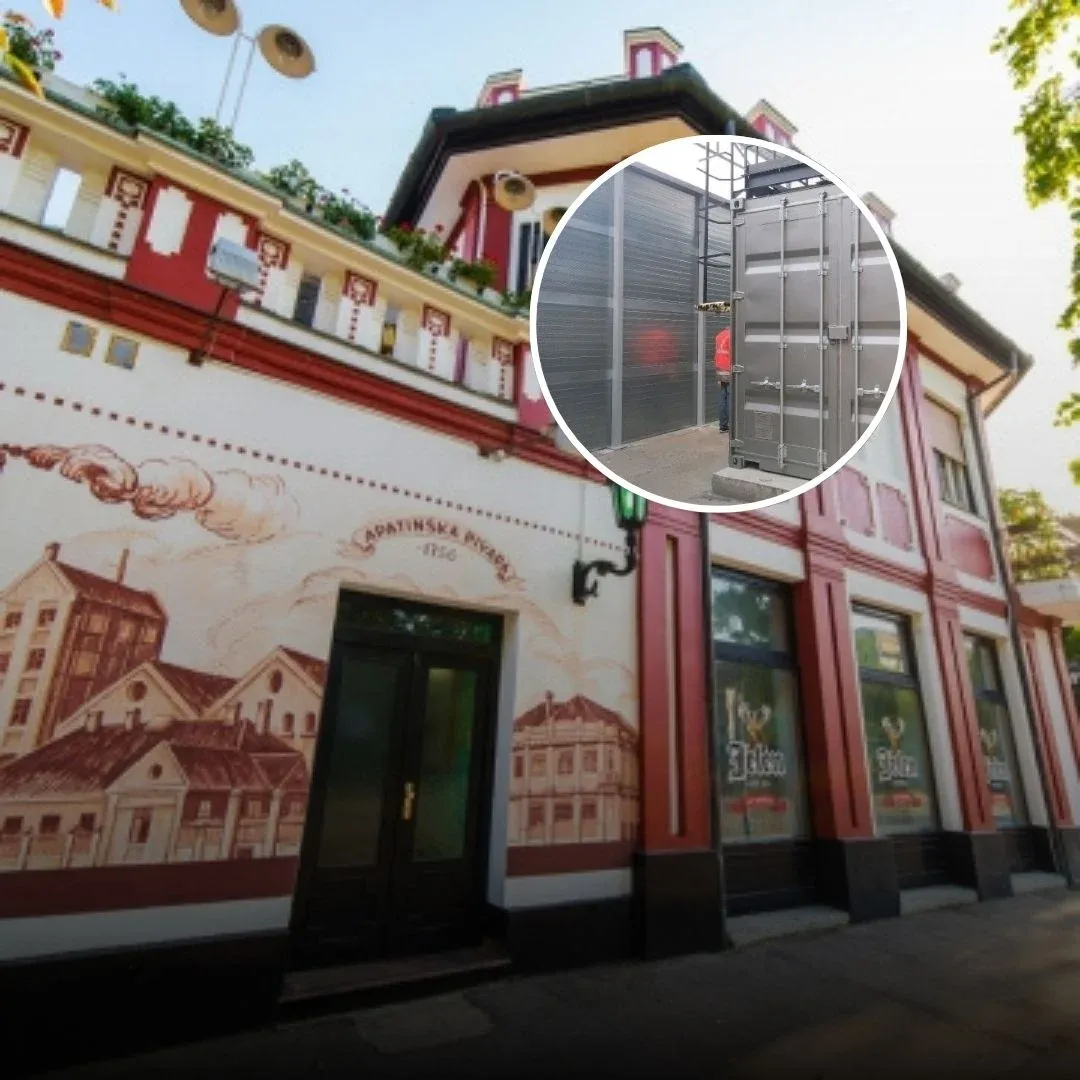

- Compressor, chiller, and generator enclosures

- Hydraulic pump stations

- Industrial and manufacturing facilities

- Construction and outdoor acoustic barriers

- Gymnasiums, schools, and sports halls

- Recording and rehearsal studios

- Acoustic fencing and perimeter noise control

Flexible protection for every acoustic challenge

DBB™ combines engineering precision and adaptable design, delivering a sustainable and efficient solution for environments where traditional soundproofing is impractical. Get in touch with DECIBEL to customise your DBB™ system and achieve high-performance noise reduction tailored to your space.

Technical information

| Application | |

|---|---|

| Installation | Indoor/ Outdoor |

| Composition | Polyvinyl membrane; Polyester wool |

| Colors | 22 standard colors |

| Size | 40'' х 31.5''.; Custom sizes |

| Thickness | 1'' |

| Weight | 1 lbs/ ft2 |