- Home

- »

- Projects

- »

- Power Generators and HVAC systems

- »

- Ventilation noise reduction for pharmaceutical plant

Ventilation noise reduction for pharmaceutical plant

Project Overview

Alkaloid is the largest chemical and pharmaceutical company in North Macedonia. In 2017, during regular operations at its production facility located in the residential outskirts of Skopje, the company detected excessive noise levels caused by industrial ventilation systems.

Measurements showed noise levels exceeding 92 dB, and the factory’s management set a clear target: reduce the noise below 70 dB without affecting the airflow of the fans. A key constraint was that any added resistance in the airflow could cause fan shutdowns, which would interrupt critical production lines for pharmaceuticals.

After failing to identify a local supplier with the needed expertise in industrial noise control and airflow preservation, the company turned to DECIBEL’s headquarters for a solution.

Solving Industrial Noise Without Compromising Ventilation

Pharmaceutical facilities require strict environmental conditions. In this case, reducing noise from ventilation fans had to be achieved without reducing the efficiency of airflow, as any blockages would cause automated systems to shut down production.

This project required a custom-engineered solution that balanced sound attenuation with aerodynamic performance.

Challenge

The challenge was to design a system that could reduce sound levels by over 20 dB while maintaining uninterrupted airflow through the ventilation system. The client needed a solution that would not trigger airflow alarms or shut down any part of the pharmaceutical production process.

Scope of Work

- Noise measurement and data collection on-site

- Technical analysis of airflow and fan load requirements

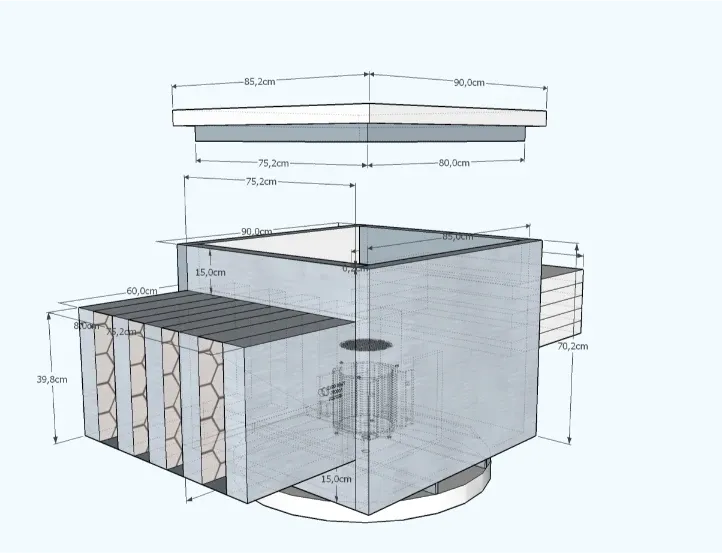

- Design and simulation of a chevron-baffle silencer system with improved internal aerodynamics

- Development of a custom silencer that could reduce noise without increasing airflow resistance

- Installation of the silencer in the fan system without interrupting operations

- Final verification of noise reduction and airflow stability

Solution

DECIBEL’s engineering team developed and installed a chevron-baffle silencer system, specially adapted with improved internal airflow dynamics. This system was based on a technology originally developed and tested by DECIBEL in 2014 at the Gornabanja mineral water factory, and later presented at the IJETCAST international scientific conference.

The silencer was designed using simulation tools to ensure it met both acoustic and aerodynamic requirements. Its construction allowed air to flow with minimal resistance, preventing any drop in performance or triggering of automated shutdown systems.

Result

The project was completed successfully, with final measurements showing a reduction in noise levels to 68 dB below the target threshold. As of 2025, no reports have been made of fan malfunctions or production stoppages due to airflow issues.

This project confirms the long-term reliability of DECIBEL’s chevron-baffle noise reduction system, especially for use in industrial environments with strict process requirements.

Ready to Reduce Industrial Noise Without Compromising Airflow?

DECIBEL offers engineered soundproofing systems for factories and industrial ventilation, designed to reduce noise while maintaining critical airflow. Contact our team to develop a custom solution.