- Home

- »

- Projects

- »

- Machinery and Industrial Buildings

- »

- Two-Stage Soundproofing for Concrete Press Machines in Czech Republic

Two-Stage Soundproofing for Concrete Press Machines in Czech Republic

Project Overview

A production factory of Diton in the Czech Republic was experiencing significant noise issues from two concrete-pressing machines.

The noise levels were disturbing residents living 200–300 metres away, where sound pressure levels measured 48 dB in front of the nearest house.

DECIBEL was tasked with reducing the external sound levels to between 35 and 40 dB to ensure acoustic comfort for the local community.

Challenge

The two machines inside the hall generated an internal sound pressure level of 116 dB. One of the machines was enclosed with thermal panels, while the other was partially closed with concrete blocks; yet, the measures were insufficient.

The challenge was to implement a staged solution that reduced reverberation inside the hall and controlled external noise transmission without interrupting the production process.

Scope of Work

- Acoustic evaluation of noise inside the production hall and at residential receivers

- Proposal of a two-stage soundproofing solution

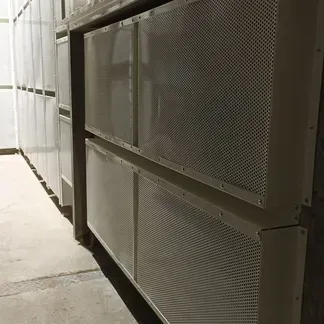

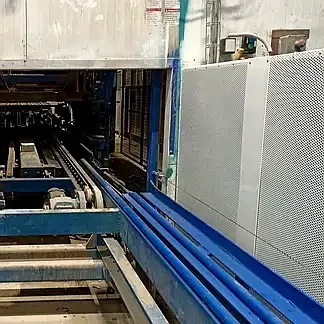

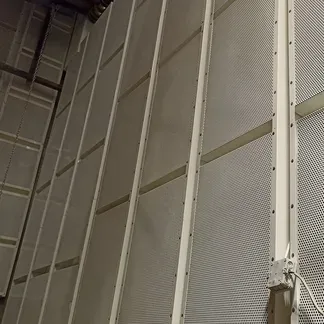

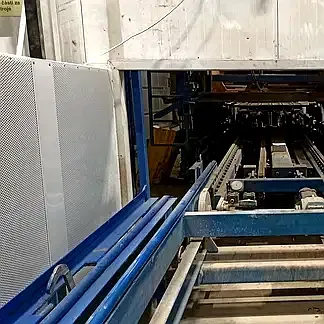

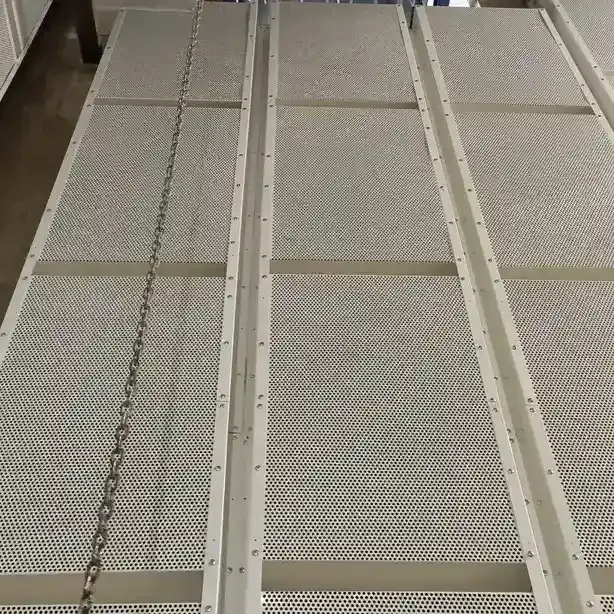

- Stage one: installation of metal perforated panels 50 mm without a back side on walls and ceilings, where possible

- Stage two: replacement of existing sectional doors with two sectional soundproofing doors with a sound reduction index of 25 dB

- Engineering design, supply, and installation of the prescribed solutions

Solution

DECIBEL’s engineering team proposed a phased approach. In the first stage, metal perforated panels 50 mm thick were installed on the walls and ceiling to reduce reverberation time within the hall. This lowered the overall sound energy escaping from the building.

In the second stage, the existing sectional doors were replaced with sectional soundproofing doors featuring a 25 dB reduction index. This provided a significant barrier against airborne noise escaping through one of the weakest points in the hall’s structure.

Result

The two-stage solution ensured that noise levels in front of the nearest residential property were reduced to the target range of 35–40 dB.

Residents benefited from a quieter living environment, while the factory maintained full operational capability.

The project demonstrates DECIBEL’s expertise in combining internal acoustic treatments with structural soundproofing upgrades to achieve measurable results in complex industrial settings. This project was done in collaboration with our partners from POTICHU.

Get in touch for professional industrial soundproofing!

Related Products

PZP™ – Perforated Galvanised Steel Panel