- Home

- »

- Projects

- »

- Machinery & Industrial Buildings

- »

- Soundproofing Booth for Gorinvest JSC

Soundproofing Booth for Gorinvest JSC

Project Overview

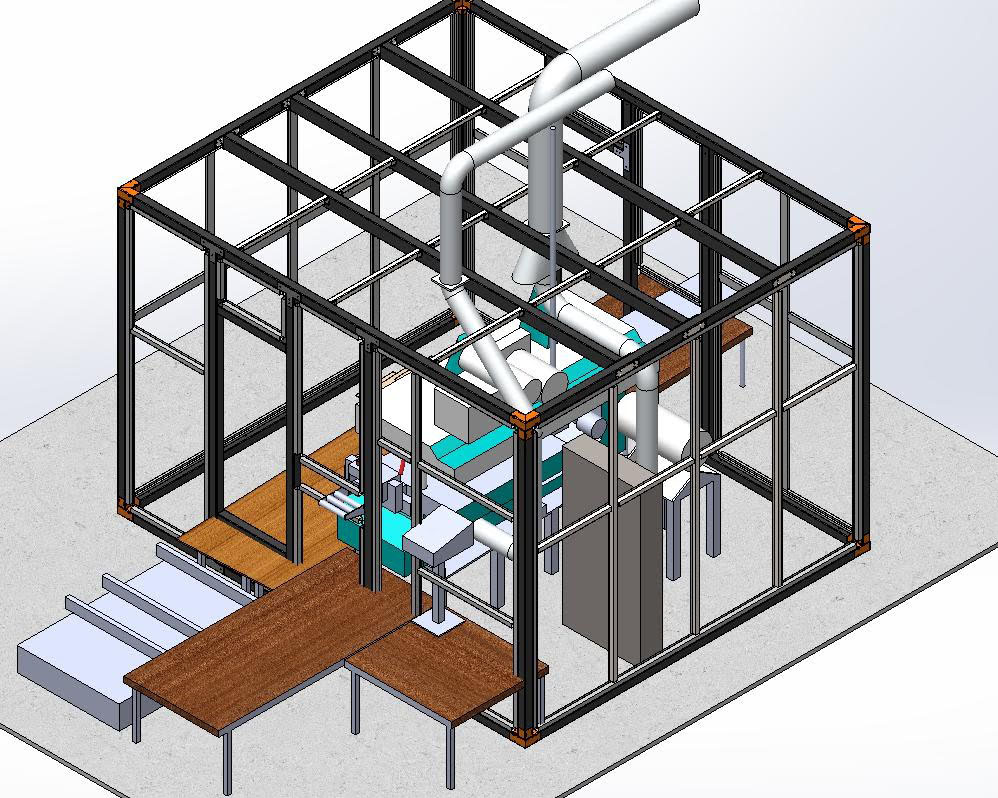

Gorinvest JSC, a leader in the forestry industry in Northeastern Bulgaria since 1998, faced a significant challenge with excessive noise generated by their Abricht machine. Noise levels peaked at a staggering 130 dB and ranged from 100 dB to 120 dB throughout the working space. Such high noise levels severely impacted employee concentration, leading to increased production wastage. To address these issues, Gorinvest JSC sought DECIBEL's expertise for a soundproofing solution.

Challenge

The Abricht machine’s noise not only posed a health hazard but also contributed to subjective errors in production, creating an urgent need for effective sound insulation. Gorinvest JSC required a soundproofing booth with the following specifications:

- A reduction of noise levels from 130 dB to 85 dB.

- Technological openings for timber entry and exit.

- Visibility for workers to observe the production process.

- Dimensions of 4m x 5m x 3.60m.

DECIBEL's engineering division was chosen for its experience and flexibility in designing soundproofing solutions.

Scope of Work

- Conducted detailed measurements of the workspace.

- Created 3D computer models of the soundproofing booth.

- Designed a booth that meets all specified requirements.

Solution

Before constructing the booth, DECIBEL’s team took precise measurements and developed 3D models to reflect the actual working environment. The proposed solution included:

- A booth constructed with noise-reducing panels and integrated metal panels for added weight, as well as PZP panels for optimal sound insulation.

- Technological openings are strategically placed to allow for the entry and exit of timber without compromising soundproofing.

- A specially designed silencer in the shape of a truncated pyramid to prevent noise from escaping.

- Two transparent sliding doors for the machine operator to monitor operations without losing sound isolation.

- Innovative panel designs to maintain the aspiration system for removing fine particles from the air.

To ensure minimal disruption to operations, DECIBEL's team worked diligently over several weekends to construct the metal structure and assemble the panels.

Results

The soundproofing booth successfully reduced noise levels to below the targeted 85 dB, creating a safer and more productive working environment. Employees could concentrate better, significantly decreasing errors in production.

Industry Insight

In the forestry industry, noise control is critical for maintaining a safe and efficient workplace. Excessive noise can not only affect employee health and safety but also lead to operational inefficiencies. Implementing effective soundproofing solutions can enhance productivity, improve product quality, and ensure compliance with occupational health standards.

If your organisation faces similar noise challenges, don’t hesitate to reach out. Our specialists can provide tailored solutions to enhance your workplace environment, ensuring both employee well-being and operational efficiency. Contact us today to discuss your sound insulation needs.