- Home

- »

- Projects

- »

- Machinery and Industrial Buildings

- »

- Noise Reduction for Kronospan’s Wood Processing Factory in Bulgaria

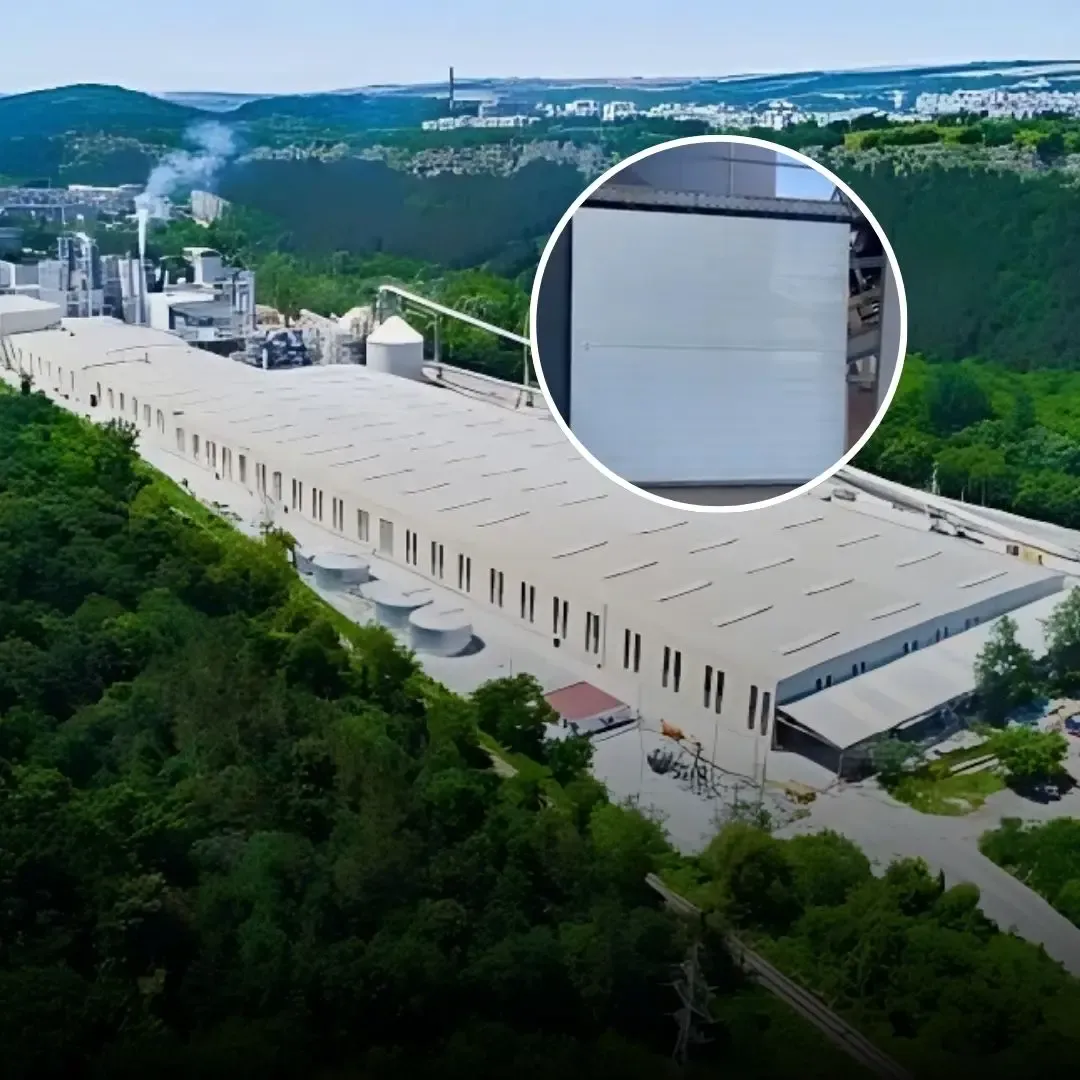

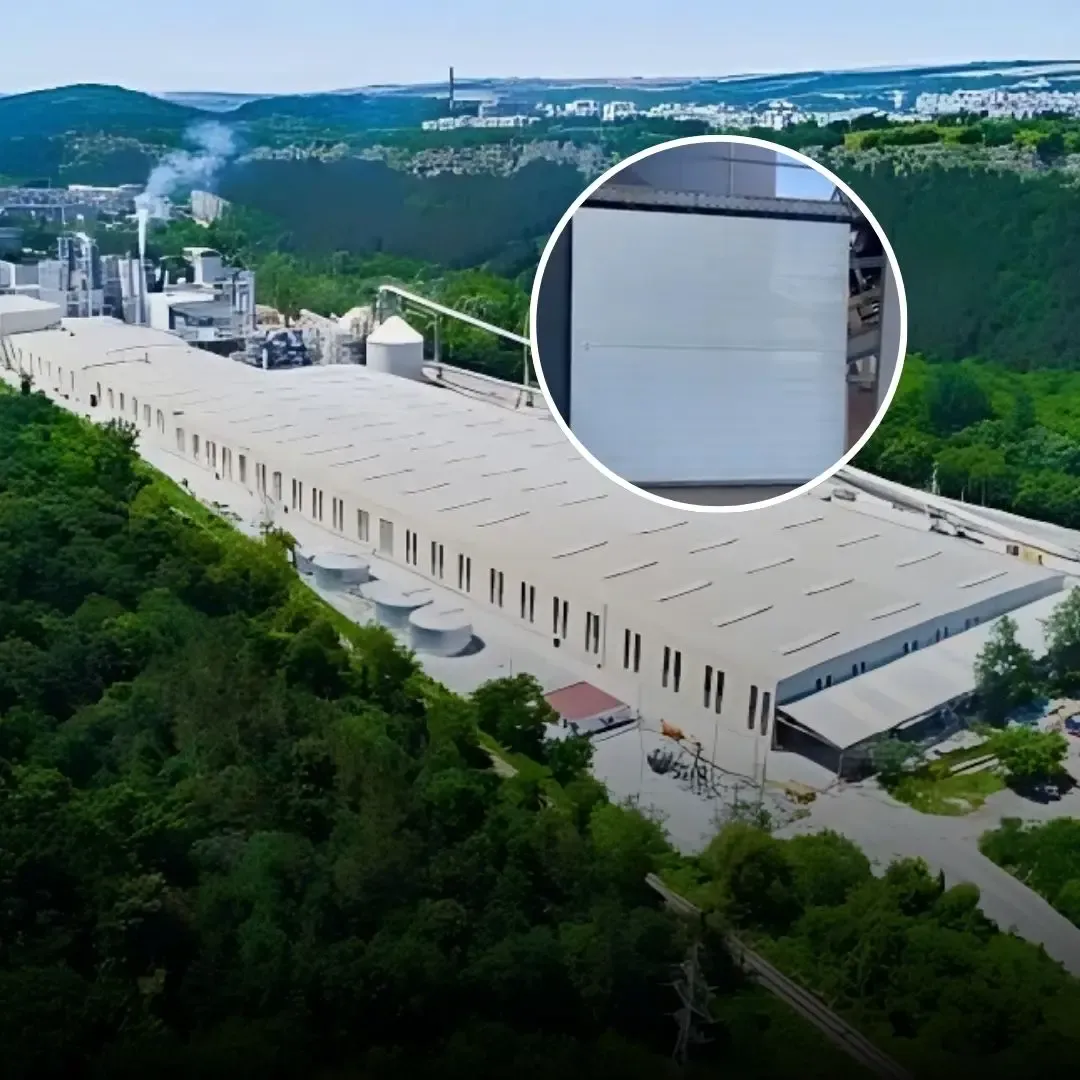

Noise Reduction for Kronospan’s Wood Processing Factory in Bulgaria

Project Overview

In one of its Bulgarian factories, Kronospan faced a significant challenge: powerful wood-processing machines were generating peak noise levels of up to 114 dB, with low frequencies surpassing 90 dB.

This excessive noise not only impacted employees working close to the machines but also disturbed nearby residential areas.

As a leading European manufacturer with a commitment to reducing environmental impact, Kronospan decided to act. They turned to DECIBEL to engineer a comprehensive noise control solution that would reduce sound pollution and protect both workers and the community.

Challenge

The key challenge was the extreme sound pressure generated by the wood-processing machinery, which included both high-intensity and low-frequency noise.

Controlling this spectrum of noise required solutions that were effective inside the production halls and also reduced sound propagation to neighbouring residential areas.

Scope of Work

- Acoustic assessment and noise measurements at the factory and residential boundaries

- Prescription of noise insulation strategies for multiple machine types and areas

- Implementation of PZP Metal perforated soundproofing panels in stages, with ongoing monitoring of results

- Close collaboration with Kronospan’s team to align with environmental standards and operational needs

Solution

DECIBEL’s engineering team developed a step-by-step action plan tailored to the specific noise sources in the factory.

Custom-designed PZP Metal perforated soundproofing panels were introduced gradually, ensuring compliance with regulations while maintaining uninterrupted production.

The approach targeted both airborne and low-frequency noise, with materials and methods chosen to withstand the heavy-duty industrial environment.

Result

The staged implementation of noise insulation achieved compliance with noise standards, reducing the impact on surrounding residential areas and creating a quieter, safer environment for employees inside the factory.

Kronospan successfully aligned its operations with its sustainability goals, reinforcing its commitment to both environmental responsibility and worker well-being.

This project illustrates the importance of proactive industrial noise management. By addressing excessive machine noise with professional noise control solutions, manufacturers can protect nearby communities, improve working conditions, and uphold their reputation as responsible industry leaders.

Related Products

PZP™ – Perforated Galvanised Steel Panel