- Home

- »

- Projects

- »

- Machinery and Industrial Buildings

- »

- Industrial Acoustic Treatment for Vehicle Testing Room

Industrial Acoustic Treatment for Vehicle Testing Room

Project Overview

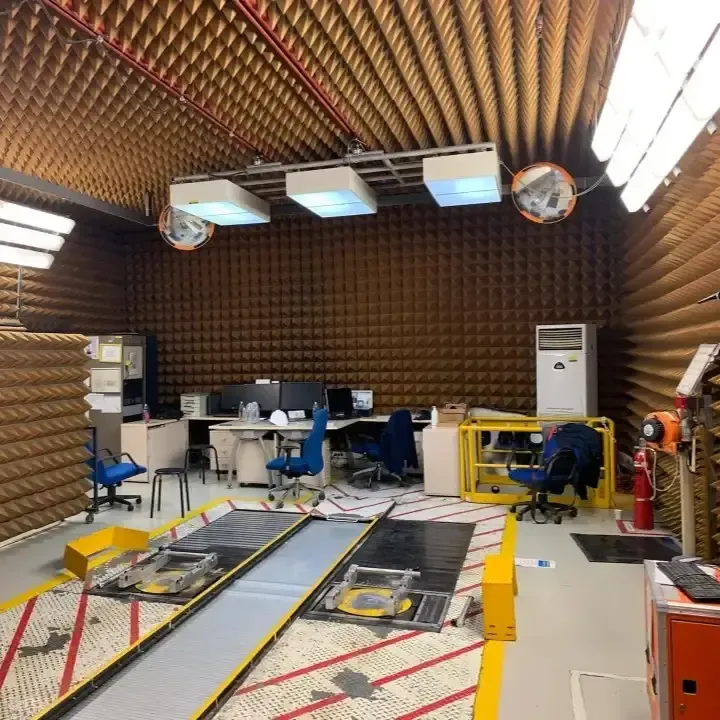

DECIBEL was selected to design and install a tailored acoustic solution for a vehicle testing anechoic chamber in an automotive manufacturing facility. The space is used to conduct sound simulations on vans, allowing engineers to detect structural issues such as loose or poorly secured components by listening for subtle noise anomalies during the test cycle.

Unlike standard soundproofing applications in studios or offices, this project required an environment where sound clarity directly impacts quality control in production. The acoustic environment had to be engineered with precision, making sure the simulation process could reliably capture even the quietest structural sounds.

Why Acoustic Treatment Was Critical

In this context, acoustic treatment was not just about improving comfort or aesthetics, it played a functional role in vehicle inspection. The test chamber acts as a controlled sound environment where vans pass over a simulated rough surface. Without effective sound insulation and noise control, the process would lack accuracy, risking undetected mechanical issues.

Challenge

Initially planned for a two-week timeline, the project faced several logistical and technical challanges that extended its completion. The most significant challenge was the restricted access to the production facility, which led to repeated pauses in installation.

The room itself presented complex architectural constraints. Many surfaces had non-standard geometries, needing custom-sized acoustic panels. Standard modular systems were not applicable. Certain wall-mounted elements had to remain fully removable, requiring a specialized engineering and a non-permanent installation approach.

Additionally, the treatment included ceilings and areas around large doors, which demanded an advanced suspension system. Load calculations, positioning, and anchoring all had to be engineered specifically for this industrial setting.

Scope of Work

-

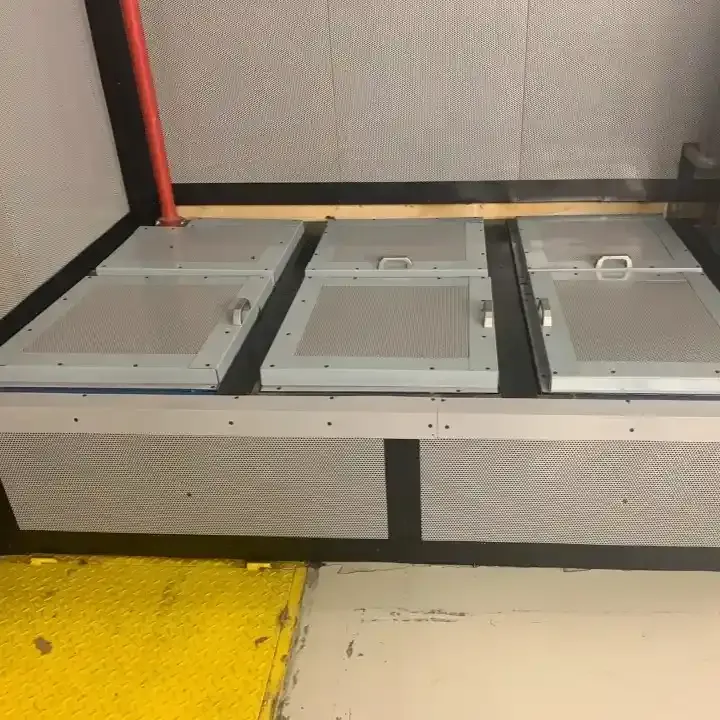

Design and delivery of metal acoustic panels tuned to a specific frequency range

-

Production of custom-sized panels tailored to the room’s geometry

-

Development of a personalised suspension system for ceilings and door zones

-

Modular installation approach to allow for partial disassembly

-

Full integration within a live production environment, meeting safety and access standards

Solution

DECIBEL used an approach that combined functional acoustic design, engineering precision, and flexible logistics. Through close collaboration between our acoustic specialists and the engineering team, DECIBEL implemented a modular acoustic system capable of capturing the slightest structural noise during simulation testing.

The solution involved the installation of custom acoustic panels engineered for the specific sound profile of the testing chamber. These panels are both technically advanced and visually adapted to the industrial setting. The sections that were critical were made removable, allowing the space to remain functional without compromising its acoustic integrity.

Result

The implementation of DECIBEL’s acoustic system significantly improved the sound quality and test accuracy within the chamber. Vehicles now pass through a controlled acoustic environment, allowing engineers to identify hidden structural noise with higher precision.

This not only optimized the diagnostic process, but also improved the confidence in the reliability of Ford Otosan’s testing procedures. The result is a powerful mix of technical excellence and acoustic control, purpose-built to support manufacturing quality at the highest level.

Explore more industrial-grade solutions in our completed project portfolio.

Ready to Optimise Your Industrial Space?

DECIBEL provides custom-engineered acoustic and soundproofing solutions for complex environments. Contact our team and let’s design precision sound together.