- Home

- »

- Projects

- »

- Machinery and Industrial Buildings

- »

- Custom Noise Control for Pulp and Paper Facility in Austria

Custom Noise Control for Pulp and Paper Facility in Austria

Project Overview

Pols Zellstoff is one of the largest producers of elemental chlorine-free (ECF) bleached and unbleached softwood sulphate pulp in Central and Eastern Europe.

Located in the federal province of Styria, Austria, the factory operates two integrated paper machines that produce both bleached and unbleached kraft paper.

Due to its central location within a residential town, noise pollution from the facility became a critical issue for the surrounding community. DECIBEL was approached to deliver custom-engineered noise control solutions for the site’s most problematic noise sources.

Challenge

The primary challenge was the number and diversity of the sound-emitting equipment. The factory had several high-intensity noise sources scattered across the premises, with 12 specific locations identified as top priority.

Each of these locations required a unique solution due to varying machine sizes, positions, and operational constraints.

The goal was to significantly reduce the noise impact on nearby residential areas while maintaining access and ventilation for the equipment.

Scope of Work

- Acoustic assessment and identification of 12 key noise sources

- Design and engineering of custom noise enclosures for each source

- Fabrication and installation of metal perforated PZP panels

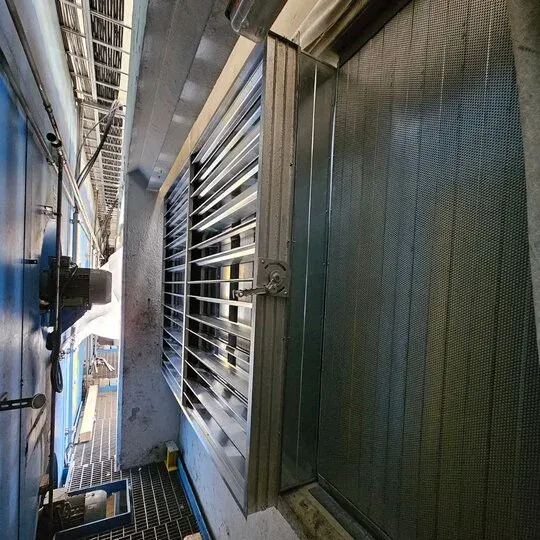

- Integration of silencers and acoustic louvres where needed

- Coordination with on-site technical teams for seamless implementation

Solution

DECIBEL’s engineering team developed individualised acoustic treatments for each of the 12 noise sources. These included soundproofing enclosures and barriers using our high-performance metal perforated PZP panels.

Where ventilation was necessary, specially designed silencers and acoustic louvres were incorporated to reduce noise transmission without restricting airflow.

The entire installation was managed in close collaboration with the Pols Zellstoff team to ensure operational continuity during the upgrade process.

Result

The project resulted in a substantial noise reduction across all 12 treated areas. Residents in the vicinity of the plant reported a noticeable improvement in environmental sound levels.

The success of the project demonstrates how targeted, high-quality soundproofing measures can effectively manage industrial noise in sensitive urban contexts.

Once again, DECIBEL delivered on its promise of engineering excellence, balancing performance, functionality, and community well-being. Get in touch for professional noise control!