Soundproofing Data Centres in the Era of Liquid Cooling

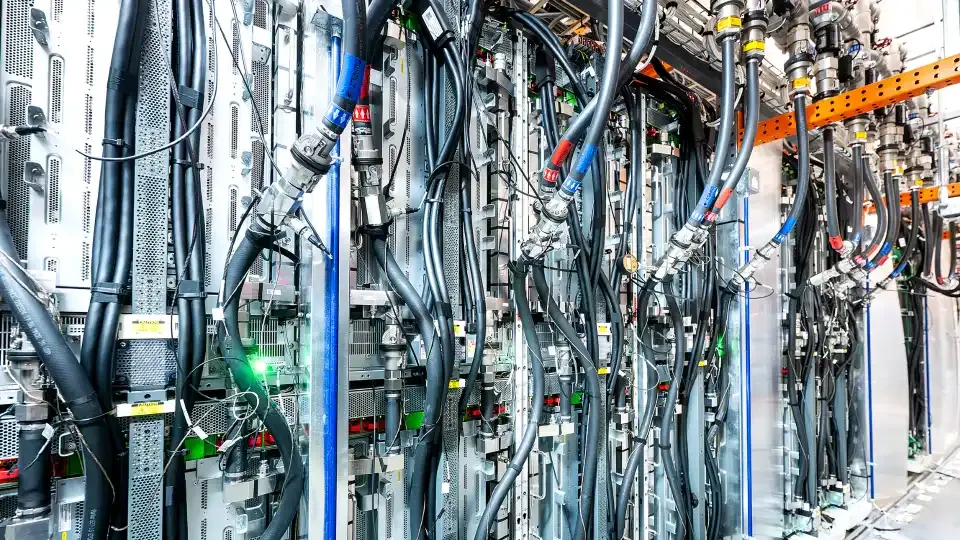

Keeping data centres cool has become a main engineering challenge as they grow larger and more powerful. Every rack, server, and storage system generates heat, and as energy use increases, traditional air-cooling systems are reaching their limits. This shift has led to a major technological evolution, which is liquid cooling.

Compared to air-based systems, liquid cooling transfers heat directly through fluid channels or immersion tanks. This offers higher thermal efficiency and lower energy costs. Yet while this innovation solves one problem, it introduces another: a new acoustic environment. Pumps, fluid flow, and coolant distribution units replace the whir of fans with buzzing, constant vibrations, and pressure noise that behave differently and need new soundproofing strategies.

This transformation, for operators and designers, means rethinking acoustic control from the ground up. Soundproofing a liquid-cooled data centre focuses on maintaining balance. Thermal efficiency, accessibility, and vibration management must work together to create facilities that are quiet and reliable daily.

What Is Liquid Cooling and How Does It Change the Acoustic Profile

Liquid cooling is quickly replacing traditional air cooling in modern data centres. It removes heat more efficiently by using coolants that flow through pipes, distribution units, or immersion tanks, transferring heat directly away from electronic components. This approach allows facilities to handle denser computing loads while using less energy.

On the other hand, from an acoustic perspective, liquid cooling changes everything. Instead of large fans and air handlers producing broadband airflow noise, the main sound sources now come from pumps, valves, and coolant movement. The acoustic energy shifts from high-frequency air noise to low-frequency mechanical vibration. This is a more complex challenge to manage.

Different liquid cooling methods generate different acoustic patterns:

- Direct-to-chip cooling lowers airflow noise but introduces pump motor hum and vibration through connected piping.

- Coolant distribution units (CDUs) create consistent background noise from fluid movement and pressure regulation.

- Immersion cooling tanks eliminate fan noise almost entirely, but can produce flow turbulence and resonance in the liquid lines.

Traditional acoustic strategies, like absorbing panels or ventilation baffles, are no longer enough on their own. Effective soundproofing for liquid-cooled systems must target these new transmission paths with a mix of vibration isolation, acoustic enclosures and attenuators.

Acoustic Advantages of Liquid Cooling

Liquid cooling introduces new types of sound and vibration, but it also offers several clear acoustic advantages. The overall sound energy inside a liquid-cooled data centre can be lower when the system is designed and maintained properly.

One of the main benefits is the reduction in fan noise. Large air handlers and server fans are no longer needed in the same amount, which removes much of the broadband, high-frequency noise typical of air-cooled environments.

Moreover, noise sources become more localised, meaning that instead of hundreds of fans spread across multiple rooms, the main sound now comes from pumps or coolant units that can be isolated in mechanical areas. This makes it easier to design targeted soundproofing solutions such as enclosures, anti-vibration mounts, or acoustic barriers.

Liquid cooling also lowers the overall airflow turbulence in a facility, which leads to a calmer background noise level. With fewer air grilles, dampers, and diffusers, the acoustic reflections that often build up in large halls are minimised. This creates a more stable and predictable sound environment. This is a very important factor for facilities operating around the clock.

New Noise and Vibration Challenges

The move from air to liquid cooling changes where and how noise is produced inside a data centre. Instead of broad airflow and fan noise, the main sources become mechanical and hydraulic, lower in frequency but often more persistent and harder to isolate.

Pump and Motor Noise

Pumps are the centre of any liquid-cooling system. Their motors create a constant humming sound that can easily travel through floors, walls, and pipework.

Flow Turbulence and Pipe Vibration

As coolant flows through bends, valves, and fittings, it generates turbulence. These small pressure changes create pulsing noises and can cause pipes to vibrate, especially when flow rates are high. Long, straight pipe sections can also resonate like organ tubes, maximising sound rather than reducing it.

Resonance in Coolant Distribution Units (CDUs)

CDUs balance coolant pressure and temperature. Although their internal pumps, sensors, and valves can create tonal noise that repeats at specific frequencies. Over time, these resonances can stress nearby structures or affect equipment calibration in sensitive zones.

Structural and Maintenance Noise

Tightly mounted cooling equipment transfers vibration into the surrounding structure, while routine maintenance, such as flushing lines or pressure testing, can temporarily increase noise levels.

The key difference is that liquid-cooling noise behaves more like vibration energy than airborne sound. This makes it harder to absorb with traditional acoustic materials. Instead, it requires targeted solutions such as anti-vibration mounts, isolated platforms, flexible pipe connectors, and acoustic enclosures designed to contain and damp mechanical resonance.

Design Strategies for Effective Soundproofing

Designing soundproofing for liquid-cooled data centres requires a balance between acoustic isolation, vibration control, and thermal efficiency. Each component of the cooling system must be acoustically treated without affecting cooling performance or maintenance access.

Isolating Pump and Cooling Units

Pumps are among the main sources of vibration. Mounting them directly onto concrete floors allows noise to travel through the structure. The most effective approach is to install them on anti-vibration mounts and floating platforms, which minimise contact and stop vibration transfer.

DECIBEL’s spring-based isolation systems are designed for this purpose, supporting heavy machinery while maintaining stable performance. They prevent low-frequency vibration from spreading into the building, protecting both equipment and staff.

Acoustic Enclosures and Barriers

Enclosing noisy equipment helps contain mechanical noise at its source. DECIBEL manufactures custom-built soundproof enclosures that lower noise from pumps, chillers, and coolant units. These enclosures use high-density steel panels lined with sound-absorbing material to block airborne noise while allowing safe maintenance access.

For openings that must remain accessible, a steel-based acoustic silencer system is integrated at the entry point. This design provides maximum noise reduction without restricting access or ventilation.

Managing Ventilation and Airflow Noise

Even with liquid cooling, air handling remains necessary for room conditioning and equipment safety. To control ventilation noise, acoustic louvres and silencers can be installed at air inlets and outlets. DECIBEL’s AL® series louvres and LW REG attenuators reduce air movement noise without affecting airflow capacity. They are made from galvanised or powder-coated steel, offering high resistance to weather and long operational life.

Wall and Door Systems

Pump and plant rooms often share walls with monitoring or staff areas. These surfaces should be treated with soundproof panel systems such as the PZP™ perforated panels, which absorb and block airborne sound. For entry points, acoustic doors with double-seal profiles and insulated cores provide consistent performance. The combination of sealed doors and high-mass panels ensures a continuous acoustic barrier across the entire enclosure.

Retrofitting vs New Build Considerations

When planning acoustic treatment for liquid-cooled data centres, the approach differs depending on whether the facility is new or being converted from an air-cooled system. Each scenario presents unique challenges in space, access, and system integration.

Retrofitting Existing Facilities

Retrofitting older, air-cooled data centres to support liquid cooling is complex. These buildings were not designed with heavy mechanical pump systems or vibration isolation zones in mind. Space for acoustic enclosures or anti-vibration mounts may be limited, and existing structures can already transmit sound through floors, walls, and pipe routes.

In these cases, noise control strategies focus on containment and adaptation:

- Installing modular acoustic barriers or partial enclosures around noisy equipment.

- Adding flexible pipe connectors and isolation mounts to prevent vibration transfer through existing structures.

- Using acoustic panels and doors to separate mechanical areas from occupied spaces.

- Implementing acoustic louvres or attenuators on ventilation openings to manage airflow noise.

These solutions allow facilities to reach compliance standards without interrupting ongoing operations. Retrofitting can be phased gradually, targeting the noisiest areas first while keeping systems online.

Designing New Liquid-Cooled Facilities

New builds provide the opportunity to integrate acoustic performance from the start. In these projects, acoustic engineers work alongside mechanical and structural teams to ensure soundproofing and cooling systems support each other.

Key design steps include:

- Zoning: locating pump and coolant units away from occupied areas.

- Structural isolation: designing separate foundations or floating floors for vibration-heavy equipment.

- Integrated airflow design: combining silencers and louvres into ventilation systems to avoid retrofitting later.

- Material optimisation: selecting sound-insulating panels and enclosures that do not trap heat.

Balancing Acoustic Performance and Cooling Efficiency

Soundproofing in liquid-cooled data centres must not compromise cooling. Acoustic systems should manage noise without limiting airflow or causing heat build-up. Properly designed enclosures use perforated steel panels, acoustic louvres, and attenuators to allow ventilation while reducing noise.

Compliance and Standards

Noise control in data centres is a legal and safety requirement.

- The EU Directive 2003/10/EC sets a limit of 87 dB(A) for worker exposure.

- The UK Noise at Work Regulations (2005) define 80 dB(A) and 85 dB(A) as action levels.

- In the US, OSHA 29 CFR 1910.95 limits exposure to 90 dB(A) over eight hours.

- Environmental noise is also regulated under BS 8233:2014, which defines acceptable noise limits in and around buildings.

DECIBEL’s acoustic systems ensure compliance while maintaining cooling efficiency.

Monitoring, Maintenance, and Future Trends

Noise control systems require regular inspection to stay effective. Vibration mounts, silencers, and seals should be checked for wear or loosening that could transfer sound through the structure. Small shifts in coolant pressure can also raise noise levels.

Installing vibration sensors and performing periodic acoustic tests helps detect changes early. Continuous maintenance preserves compliance and extends equipment life, while making sure that data centres remain quiet, safe, and reliable in the long term.

As data centres evolve to meet the growing demand for computing power, liquid cooling has become essential for maintaining efficiency and reliability. Yet with every technical advance comes a new acoustic challenge. Pumps, valves, and coolant systems introduce low-frequency vibration and structure-borne noise that require specialised treatment.

Through a combination of vibration isolation, acoustic enclosures, silencers, and precision-engineered panels, DECIBEL provides complete solutions for this new generation of facilities.

From the early design phase to long-term monitoring, DECIBEL supports engineers, architects, and data centre operators with tailored solutions built on proven expertise.

Contact DECIBEL to design or retrofit your liquid-cooled data centre with acoustic systems that deliver safety, efficiency, and silence, all in perfect balance.

LATEST BLOGS

07.11.2025 Smart Sensors to AI Noise Control in Building Acoustics

21.10.2025 How to Improve Factory Efficiency in Industry 4.0? Noise control!

10.10.2025 Beginner's Guide to Acoustics: 10 Key Terms Explained